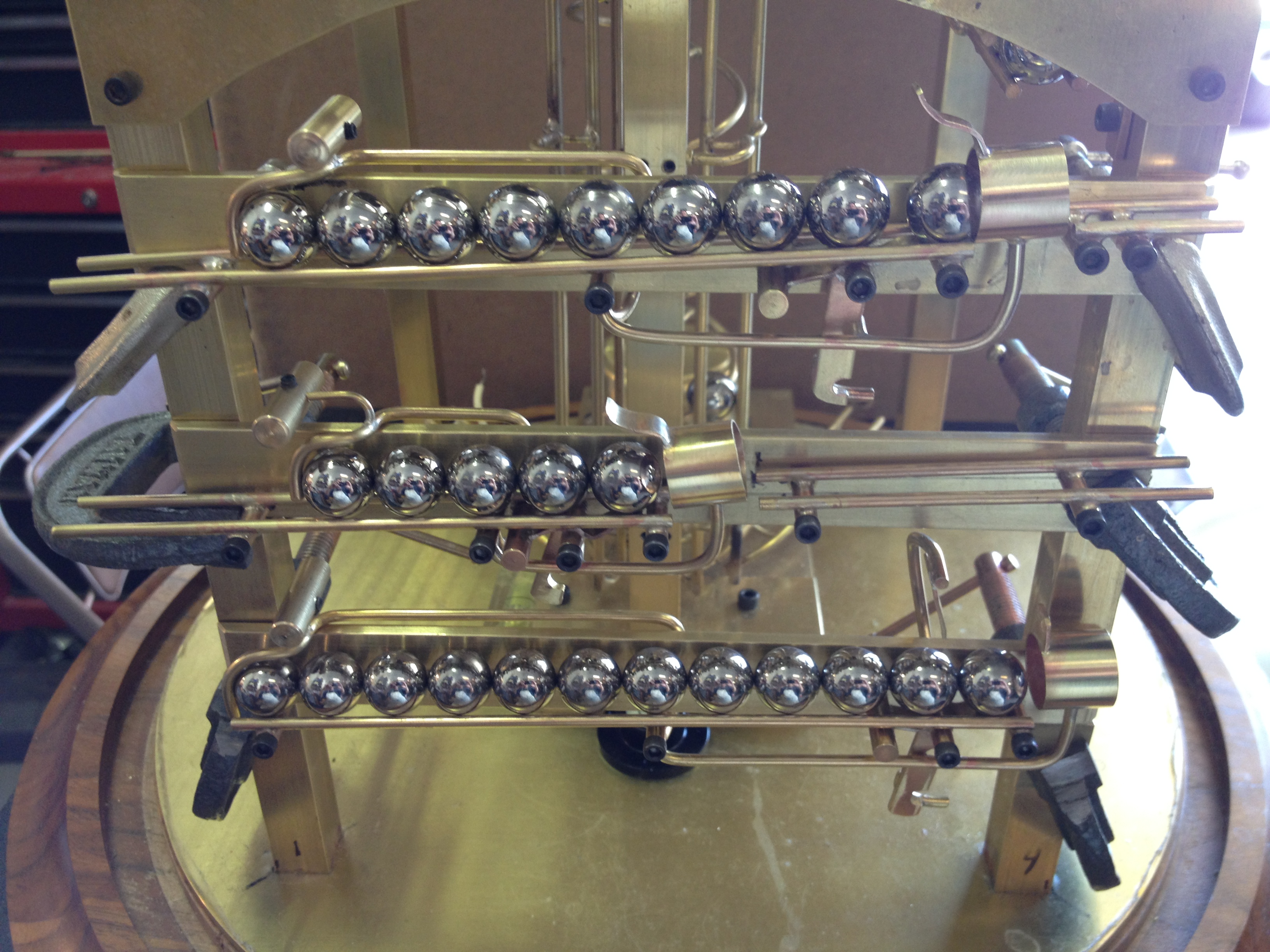

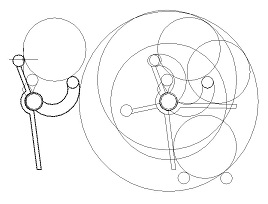

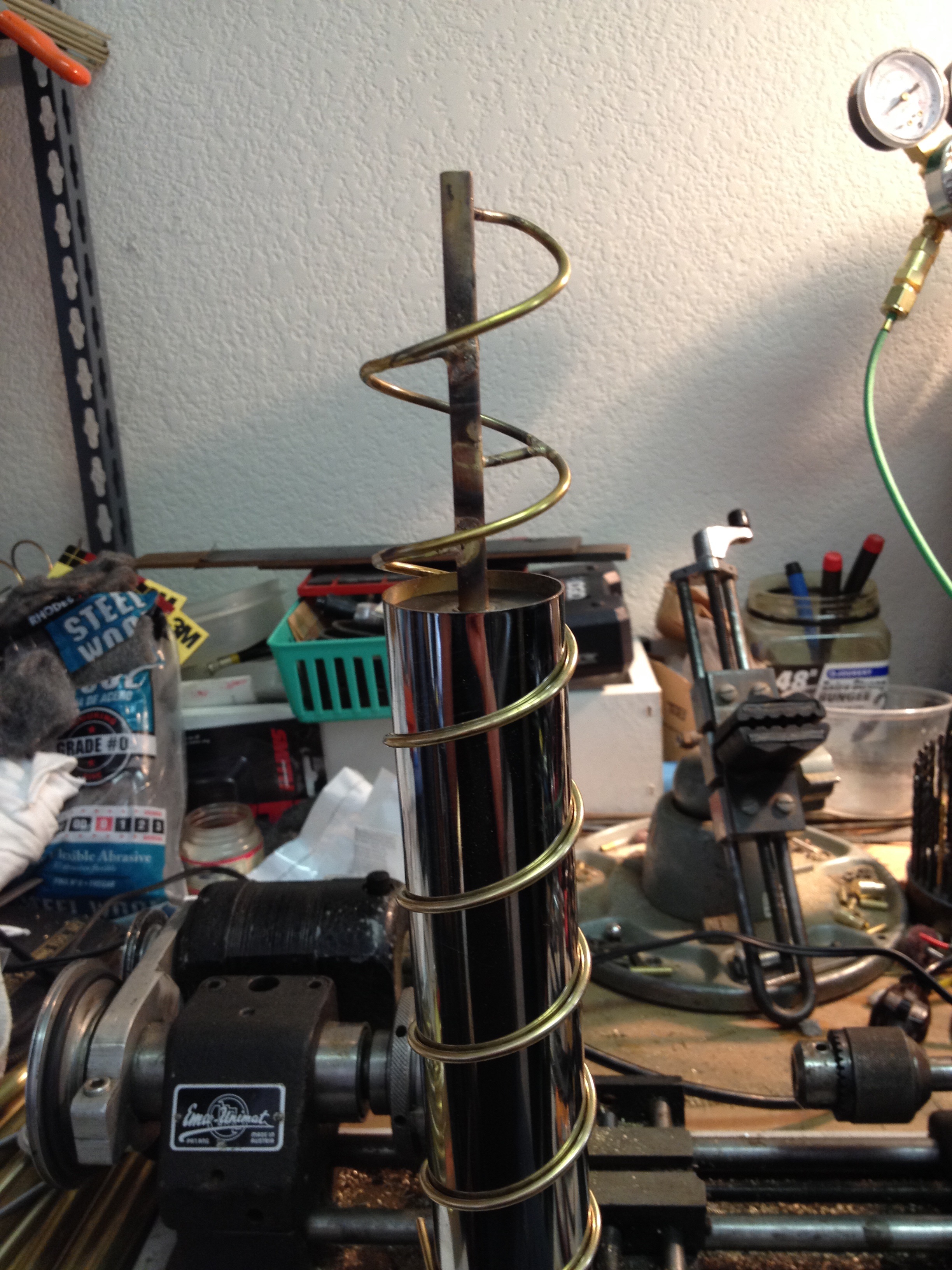

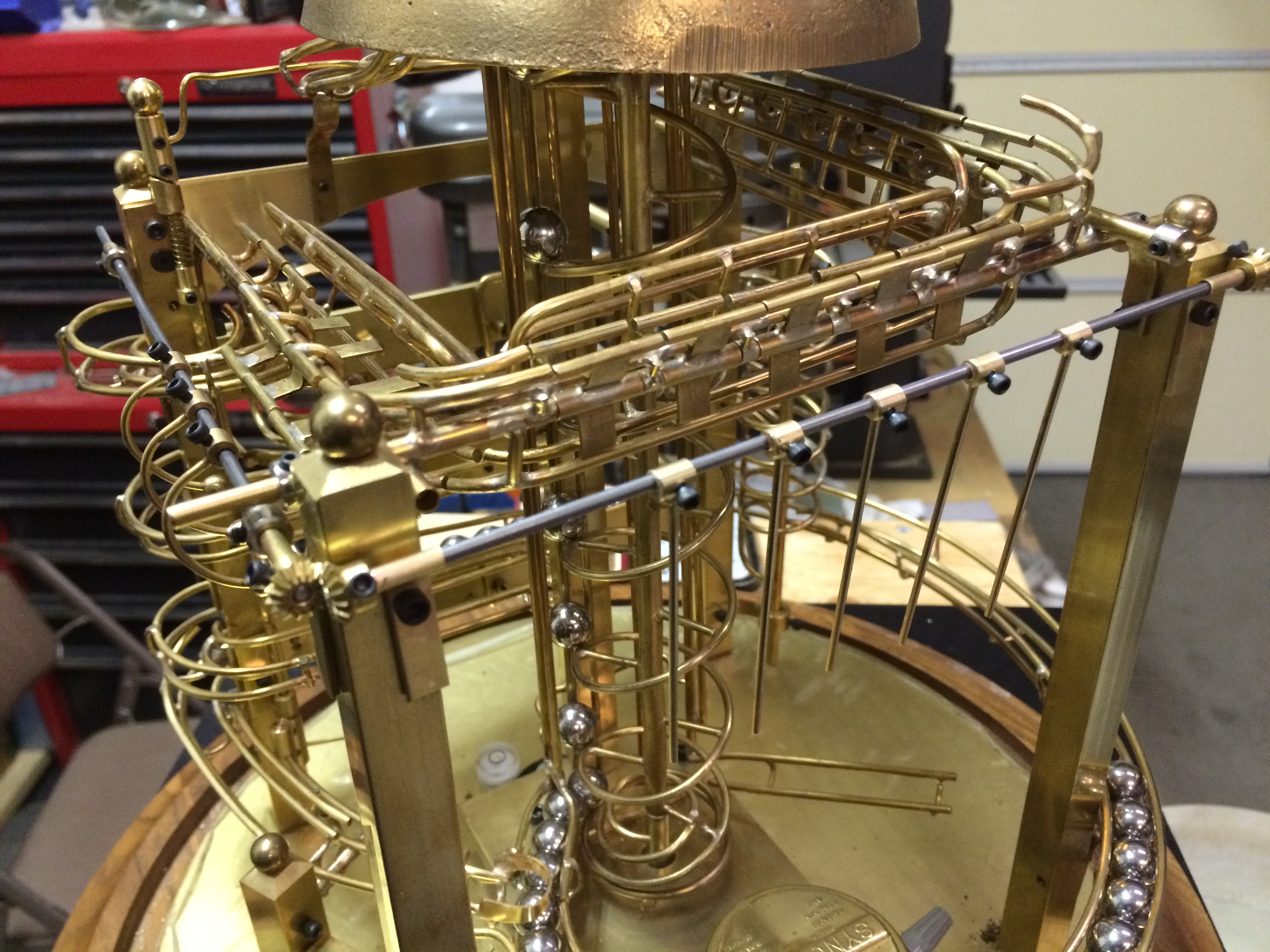

Now that the ball clock can run and keep time, the next step is to work on the counter and get it reset at the appropriate times. The concept of the counter is to have a ball flip another small section of track with every pass on the way to the minute rack. With every flip the upper track grows longer until it reaches a section that will count the 15, 30 & 45 minute passes. This is composed of three flips for that purpose. When all three of these are flipped, the ball will end up in the hour section. Don’t know what that will look like yet.

Now that the ball clock can run and keep time, the next step is to work on the counter and get it reset at the appropriate times. The concept of the counter is to have a ball flip another small section of track with every pass on the way to the minute rack. With every flip the upper track grows longer until it reaches a section that will count the 15, 30 & 45 minute passes. This is composed of three flips for that purpose. When all three of these are flipped, the ball will end up in the hour section. Don’t know what that will look like yet.

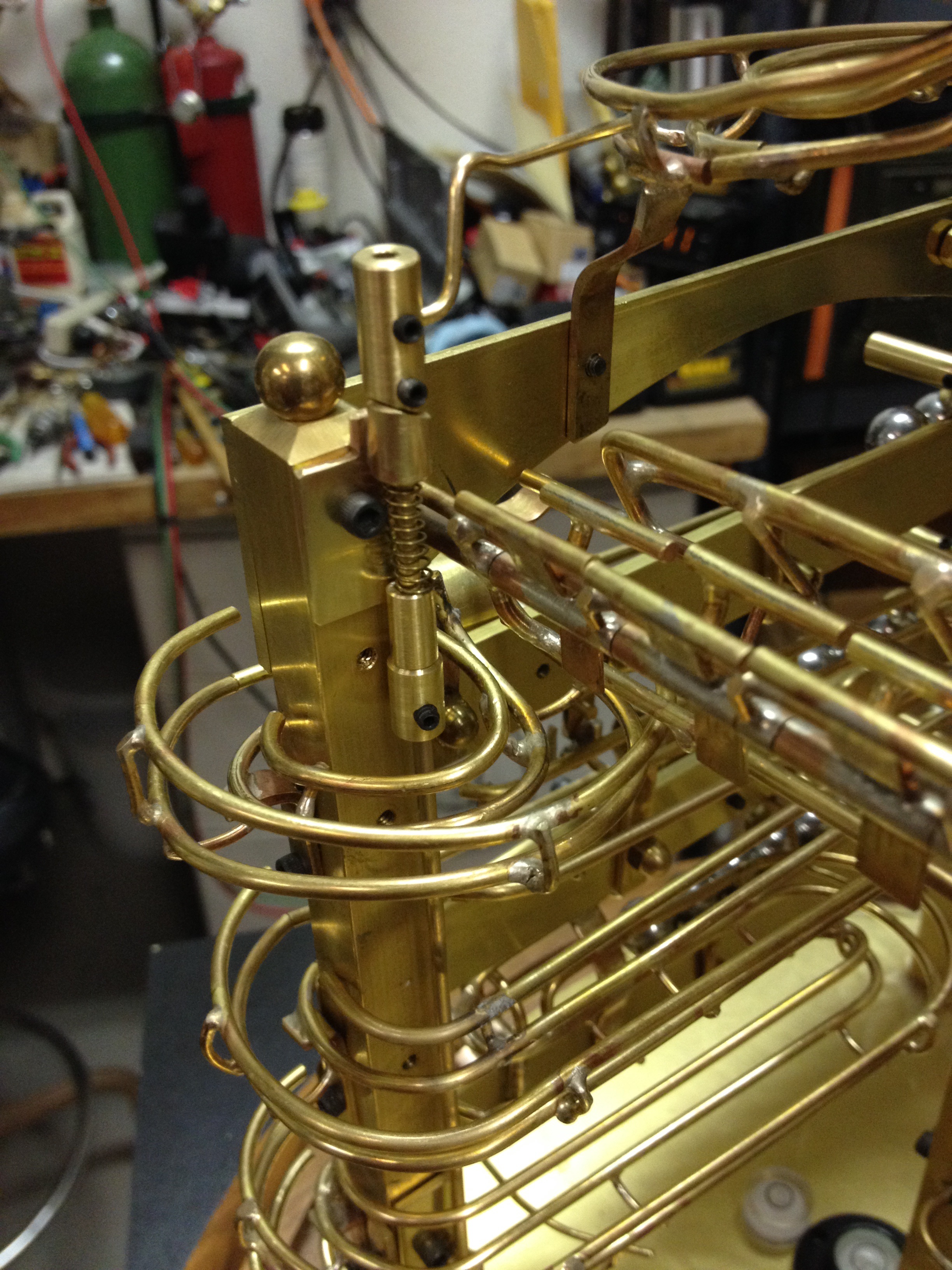

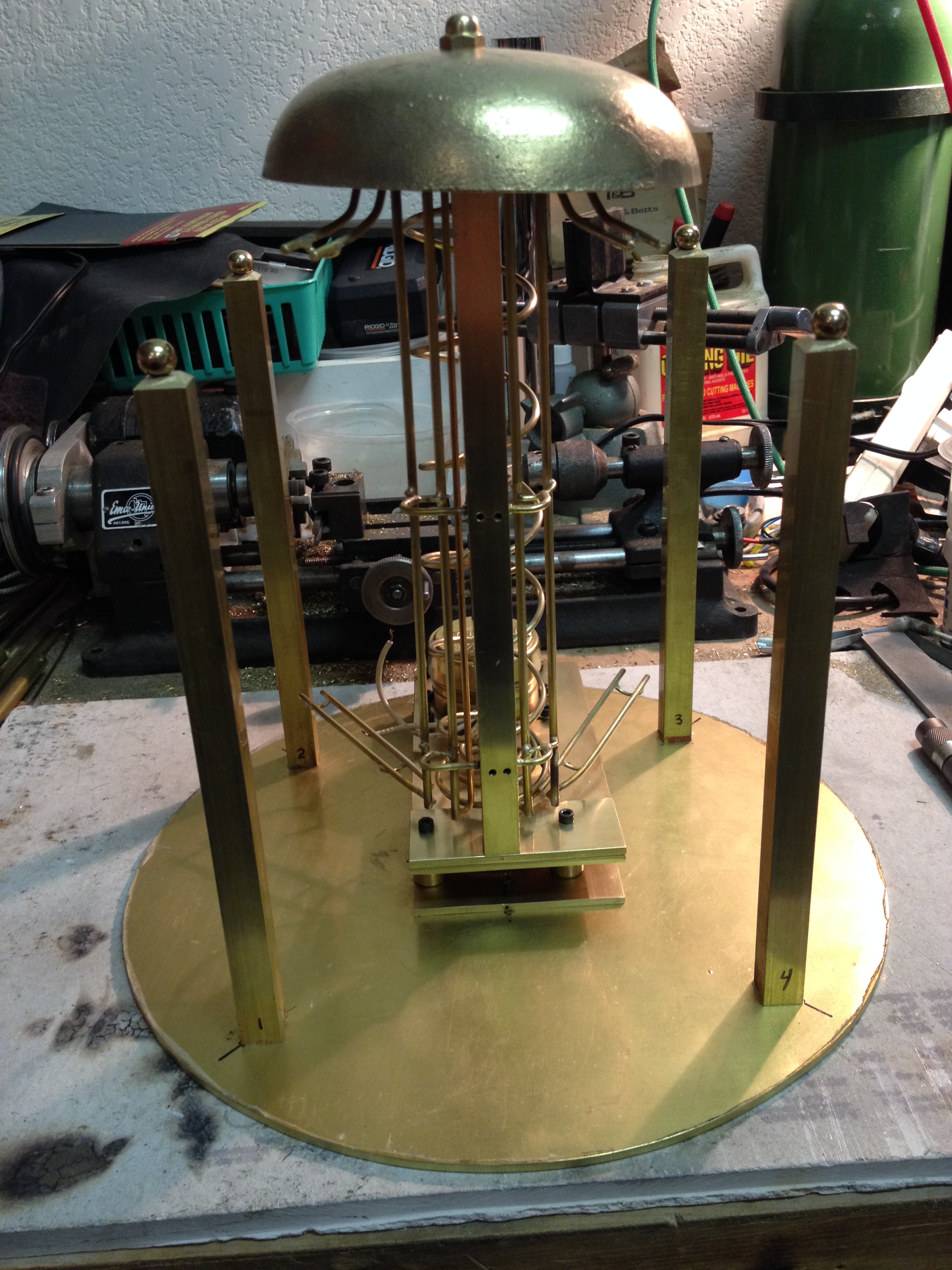

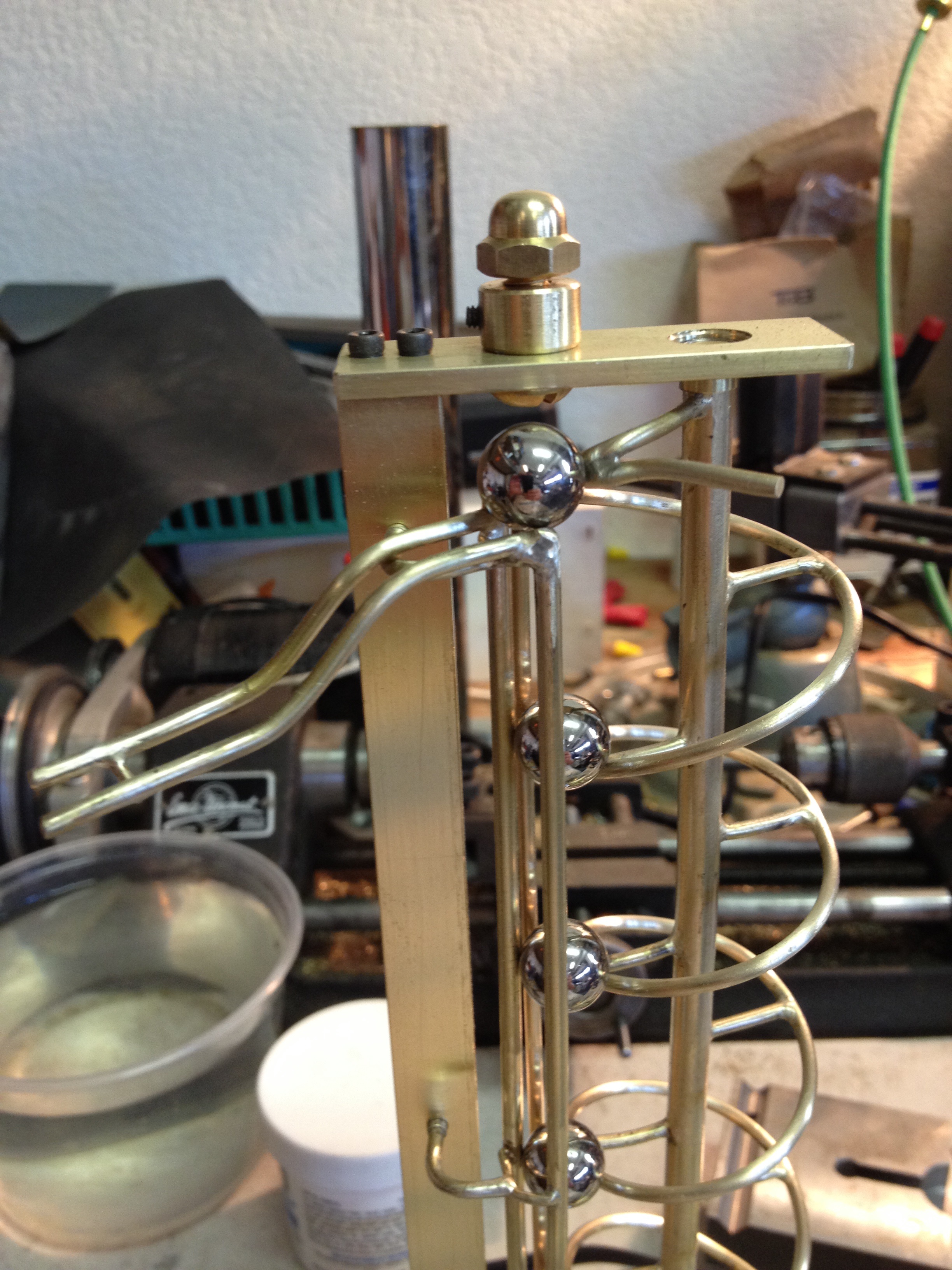

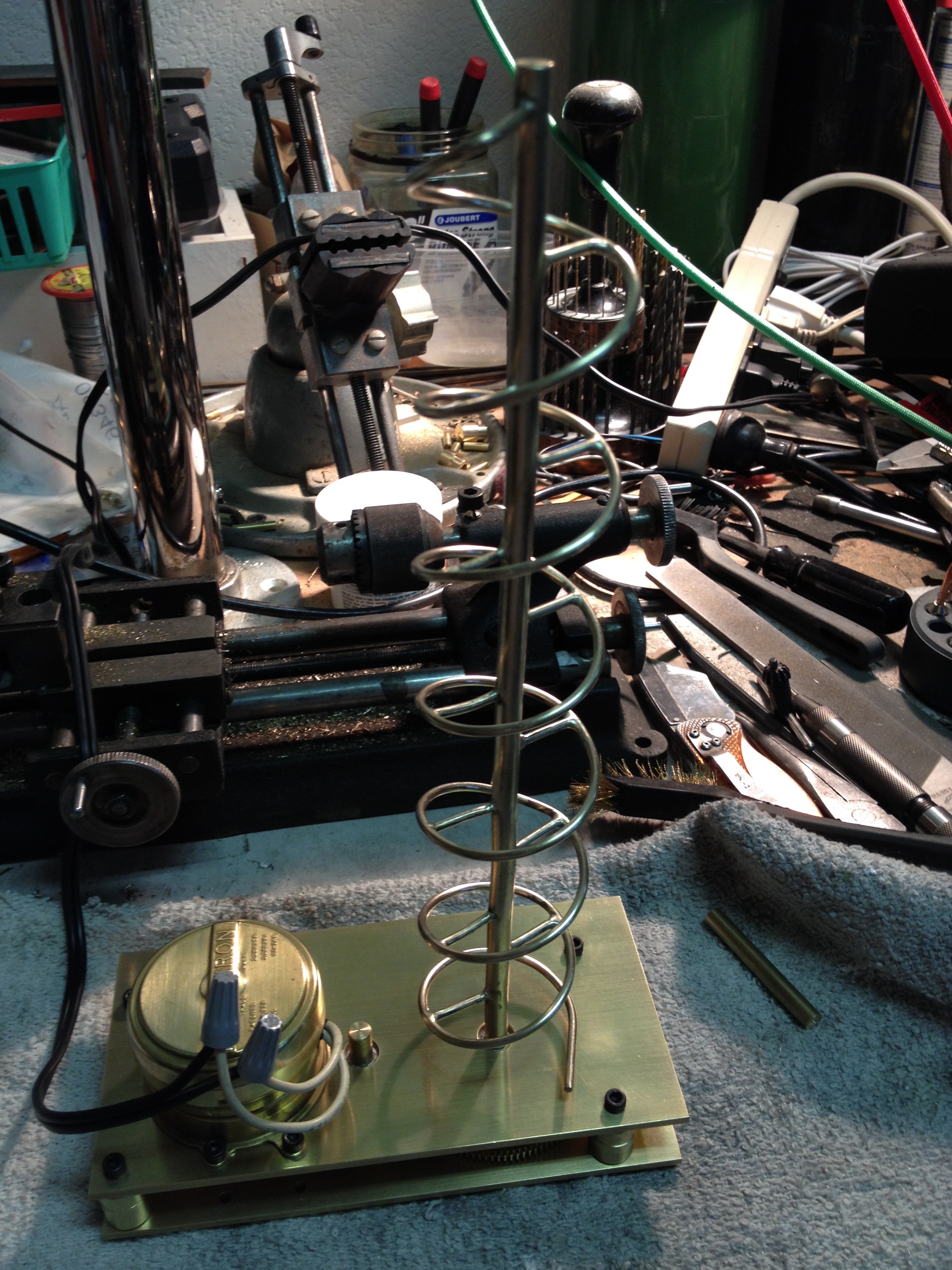

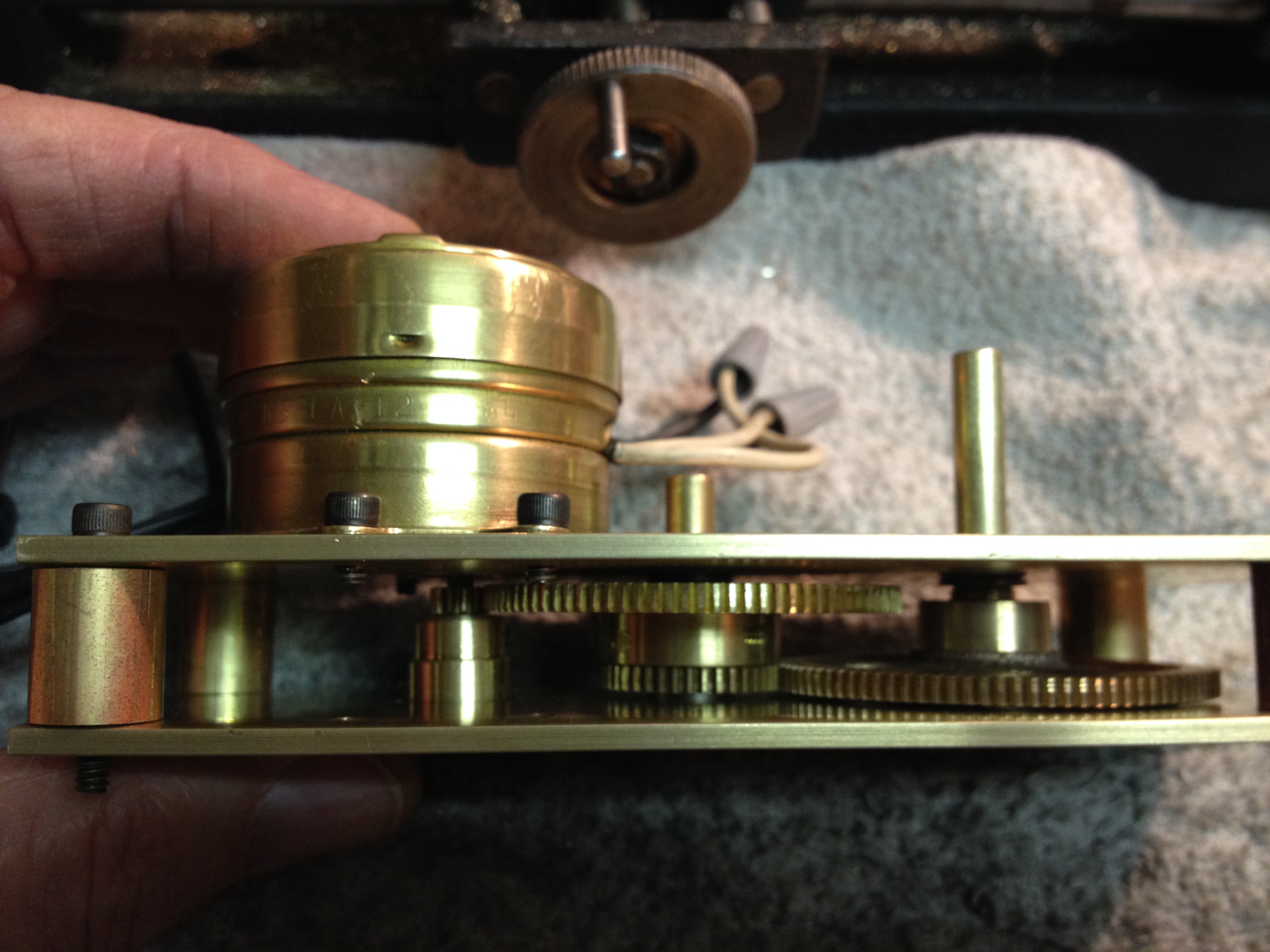

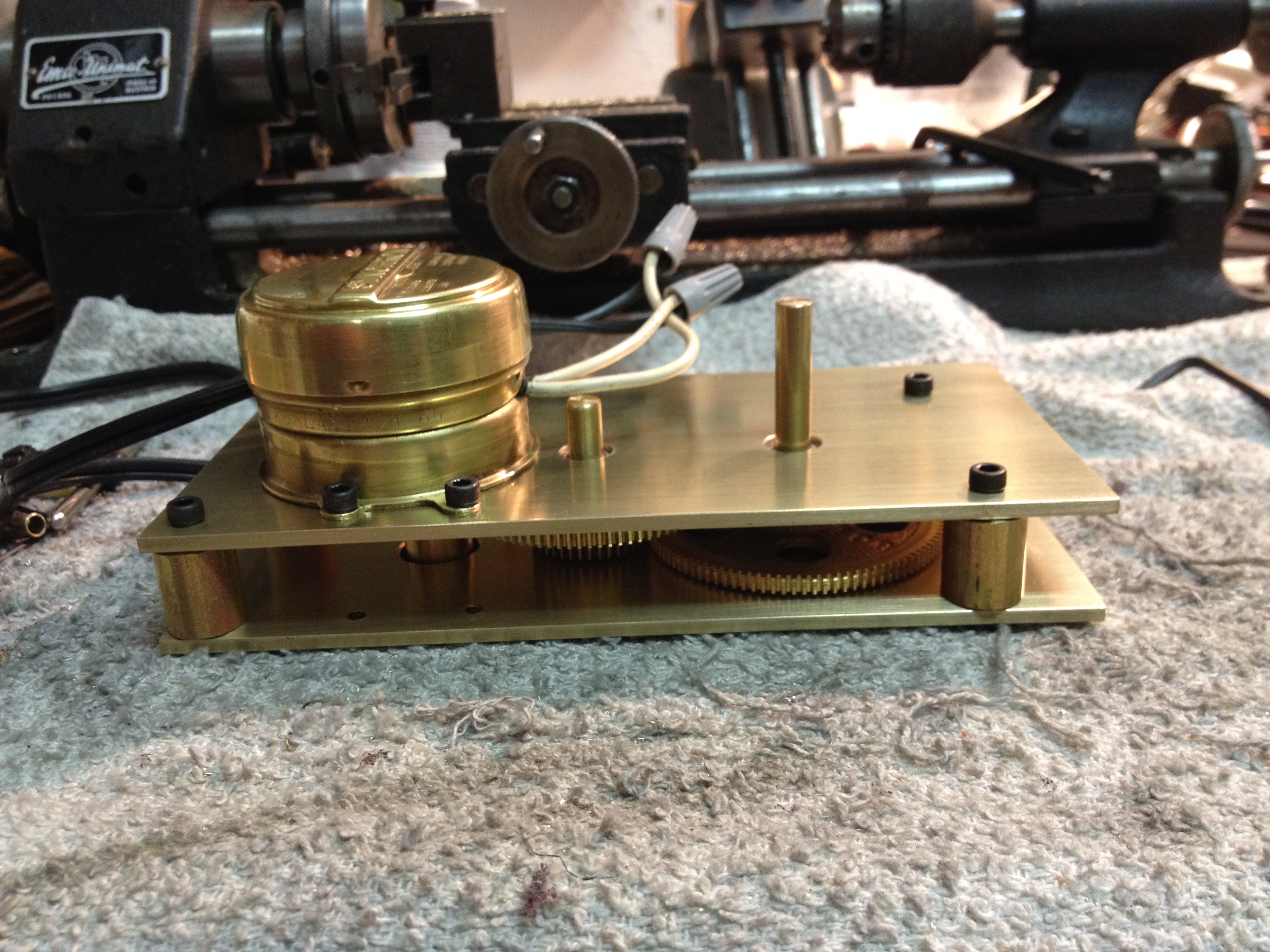

So, the first thing is to reset the flips. They are on three sides of the clock and must work in unison. Arms are created to rotate and push up from the bottom to restore the flips. Miter gears are used on two corners to rotate the shafts that will reset the flips. Because the track has a gentle slope with variances in distance from the frame, it became necessary (after a couple of attempts) to have two shafts involved. one that aligned with the track and one to provide the power for the reset.

So, the first thing is to reset the flips. They are on three sides of the clock and must work in unison. Arms are created to rotate and push up from the bottom to restore the flips. Miter gears are used on two corners to rotate the shafts that will reset the flips. Because the track has a gentle slope with variances in distance from the frame, it became necessary (after a couple of attempts) to have two shafts involved. one that aligned with the track and one to provide the power for the reset.

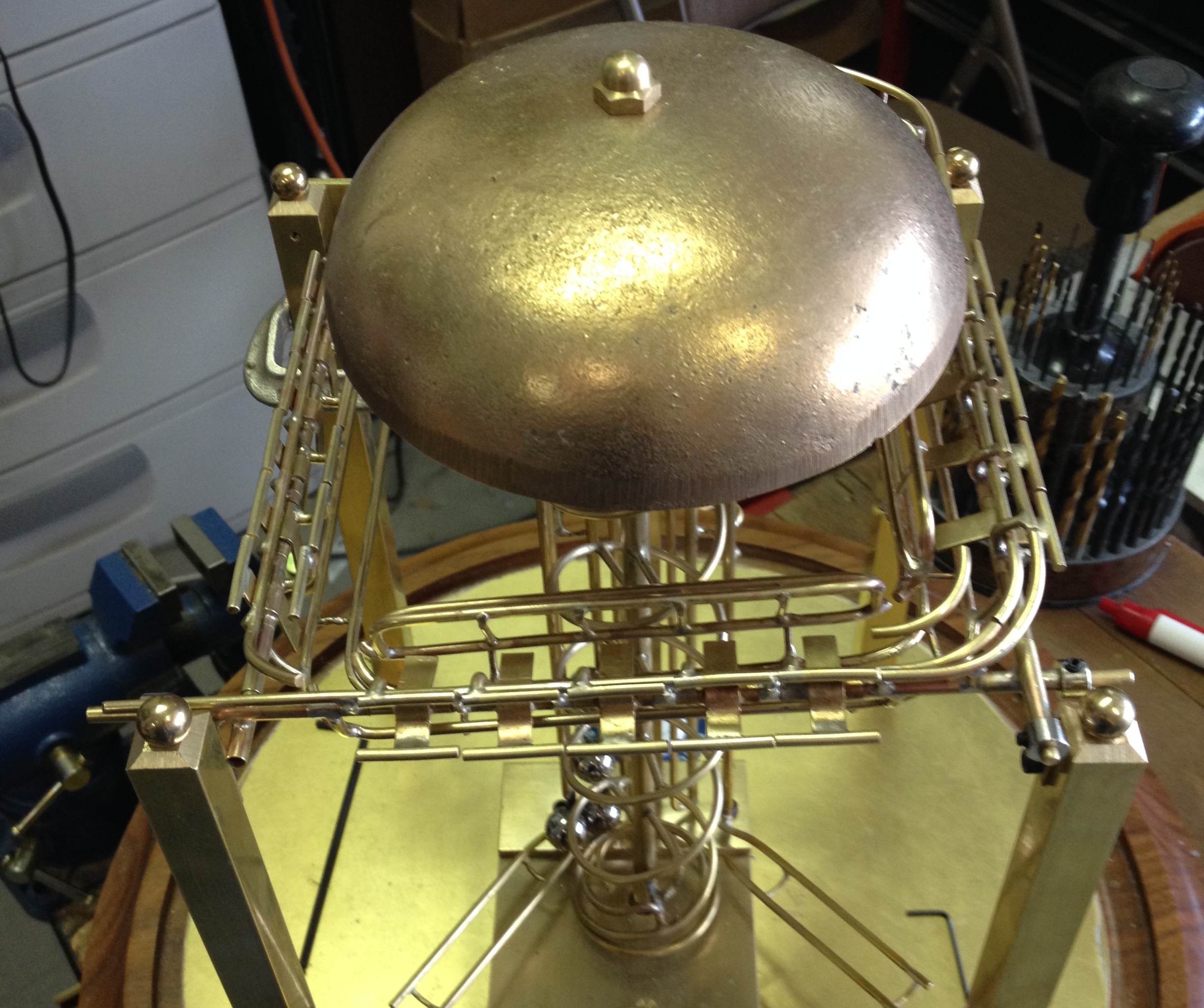

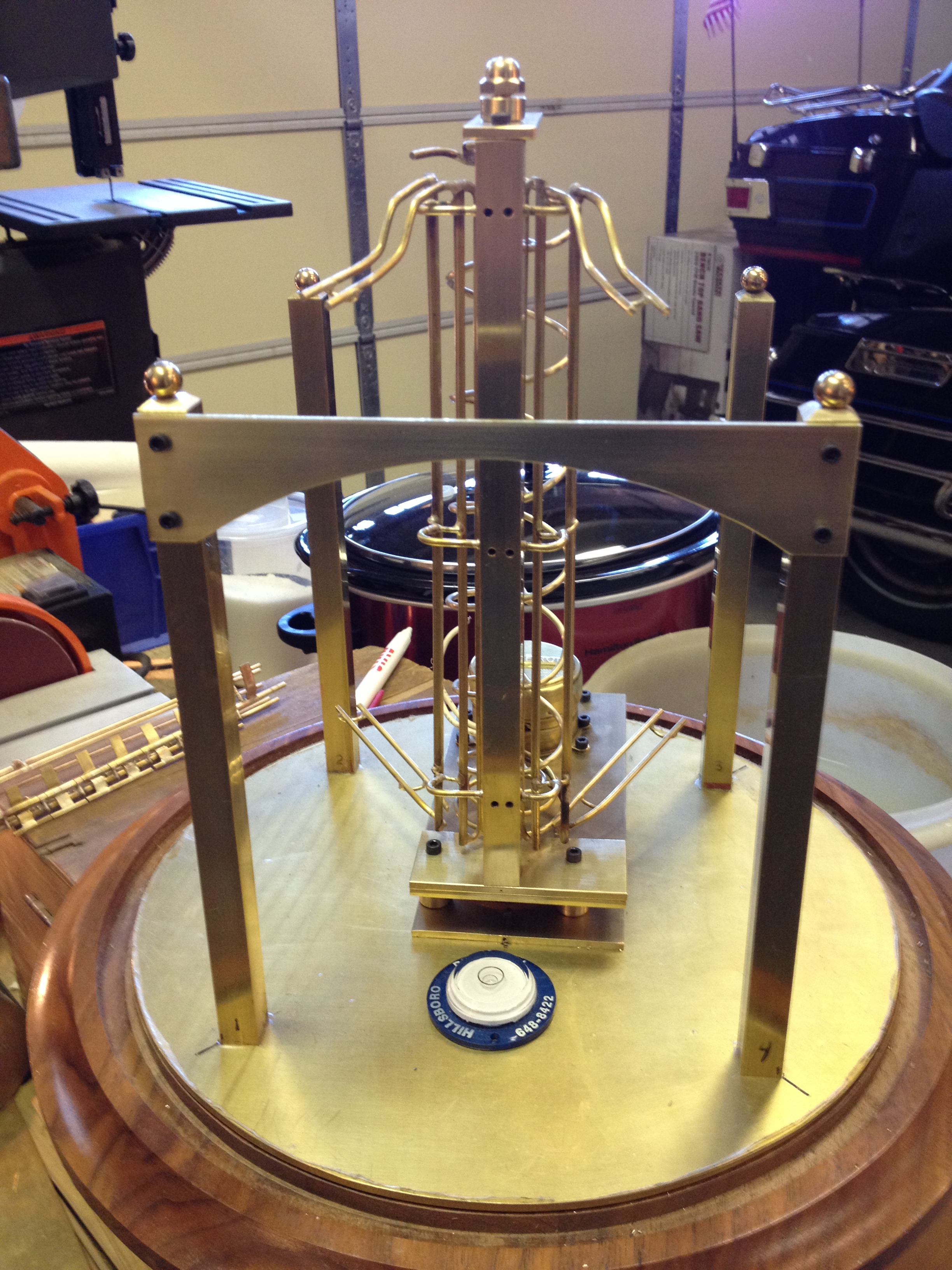

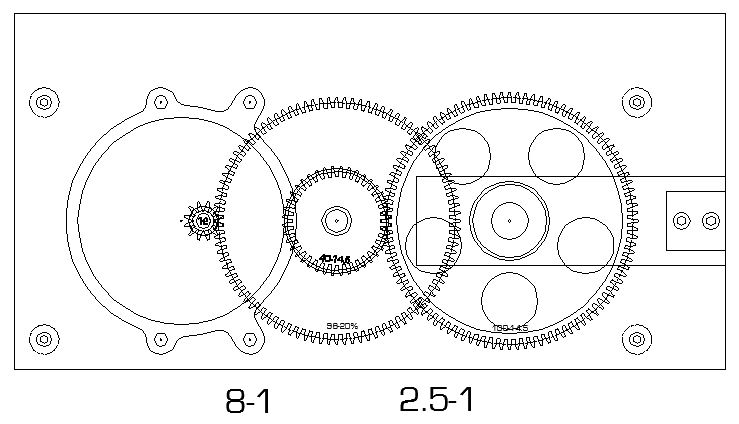

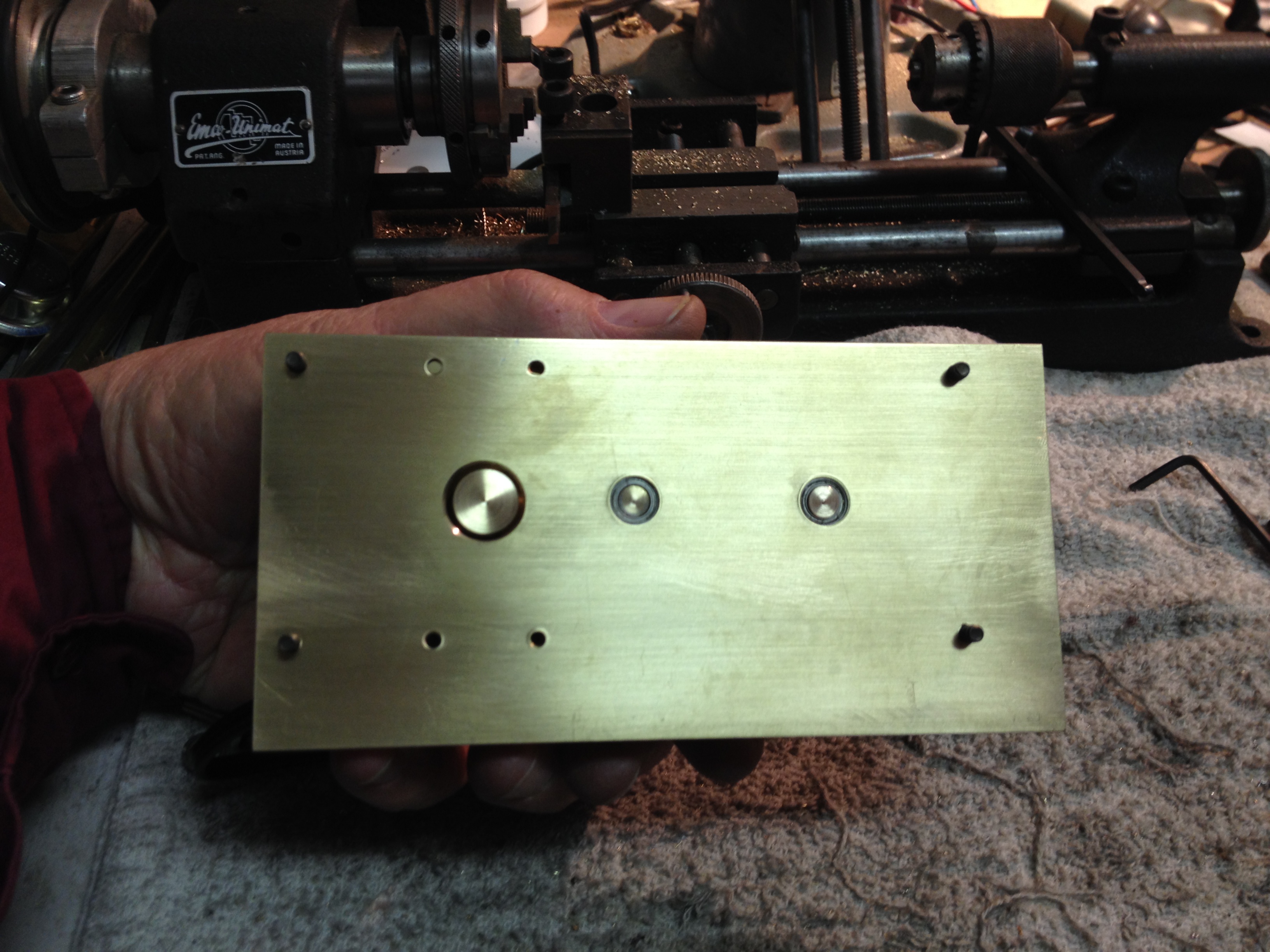

I used Boston Bevel Gears again because they are a great product and just the right size, albeit somewhat expensive at $10 each. The trick here was to create a drive train that would easily reset all the flips with a minimum of effort. Each reset arm had to be adjustable because of slight variances in the slope and flips. This is not a precision timepiece and no milling machine is being used so there are variances.

I used Boston Bevel Gears again because they are a great product and just the right size, albeit somewhat expensive at $10 each. The trick here was to create a drive train that would easily reset all the flips with a minimum of effort. Each reset arm had to be adjustable because of slight variances in the slope and flips. This is not a precision timepiece and no milling machine is being used so there are variances.

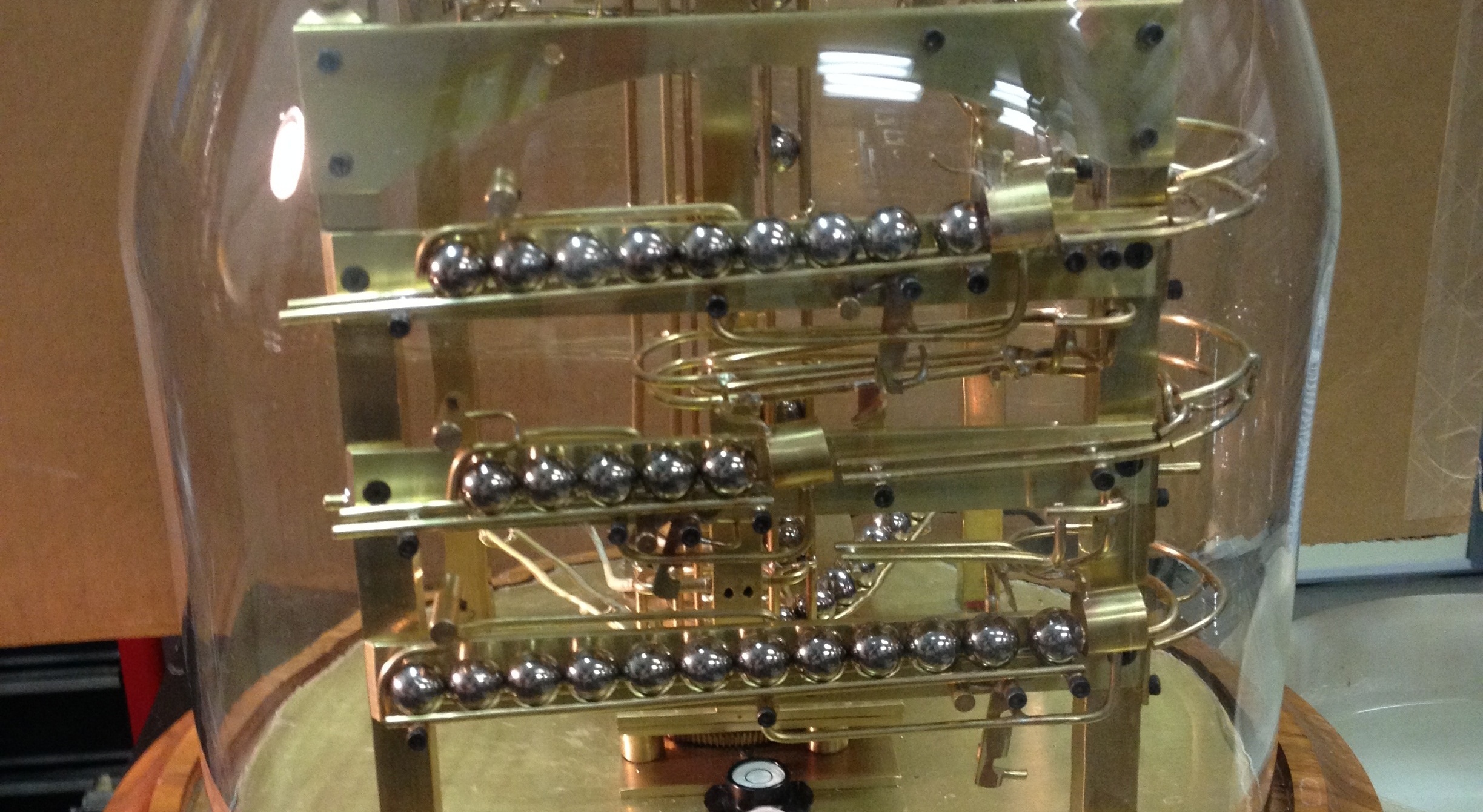

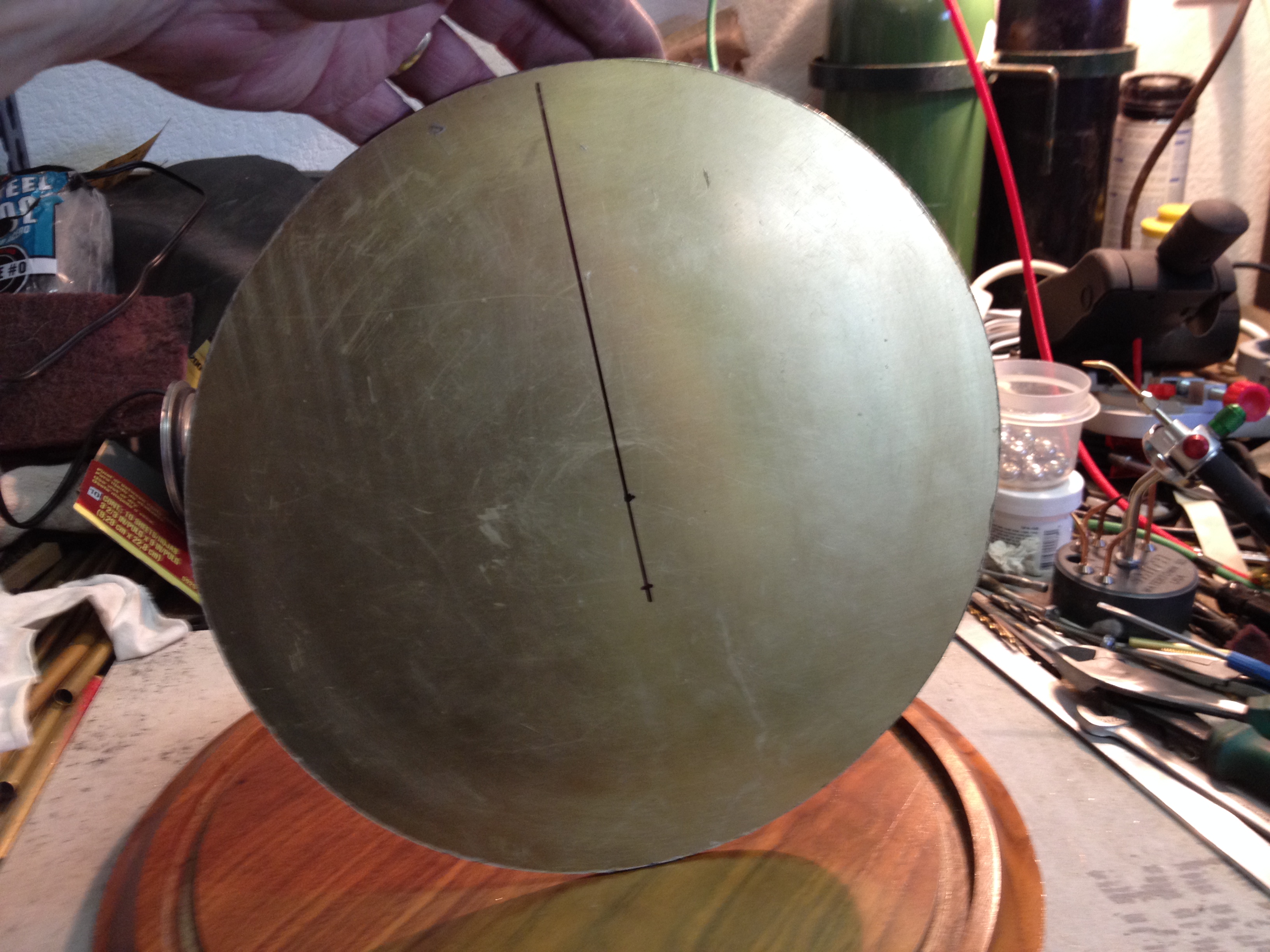

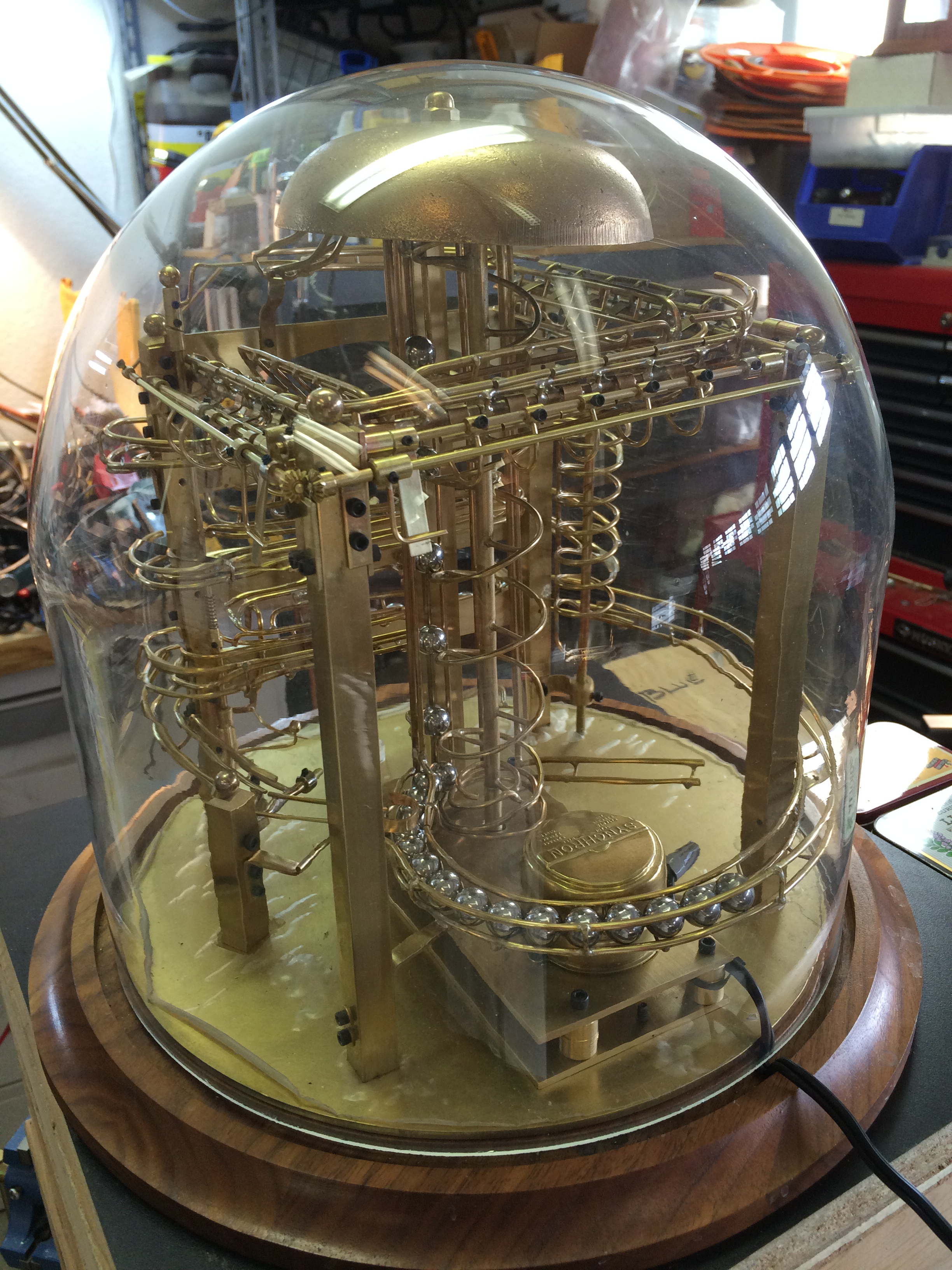

With the dome on, I check the clearance for the gears and discover that, “it is better to be lucky, than good lookin'”, sometimes. There is barely enough room as the dome curves into the top round. Having the power cord attached lifted the dome slightly and I didn’t realize just how close it was until I disconnected it.

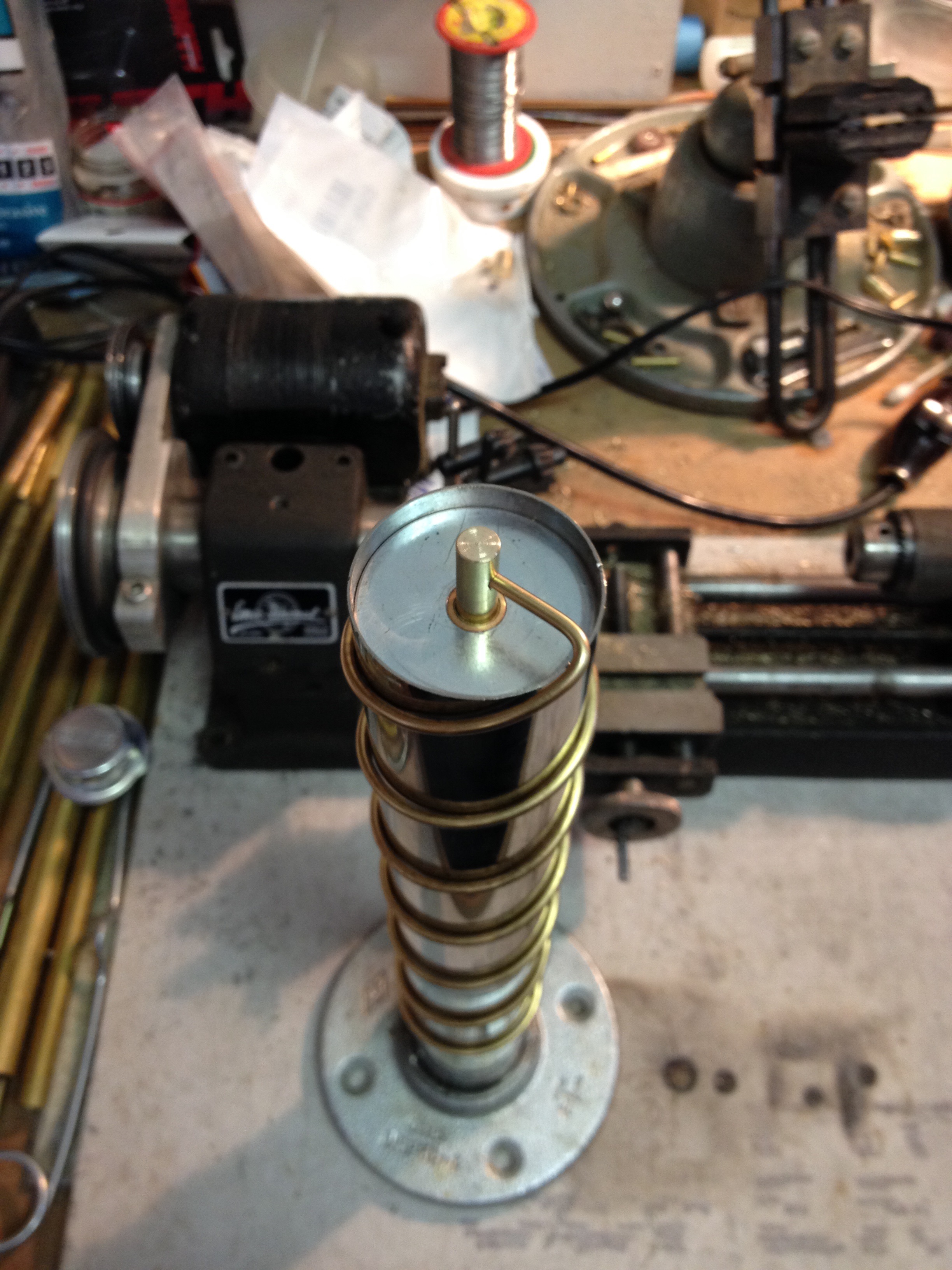

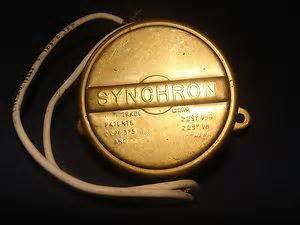

Now that I have the reset shaft assembled and working by hand, the next step is to figure out how to trip the reset at the right time. I will need power to do it and it is obvious that I do not have enough balls to do the job. Ok, so I could have said that differently.

It is obvious I will need to get power from the drive train below.

The movie shows me manually resetting the flips.