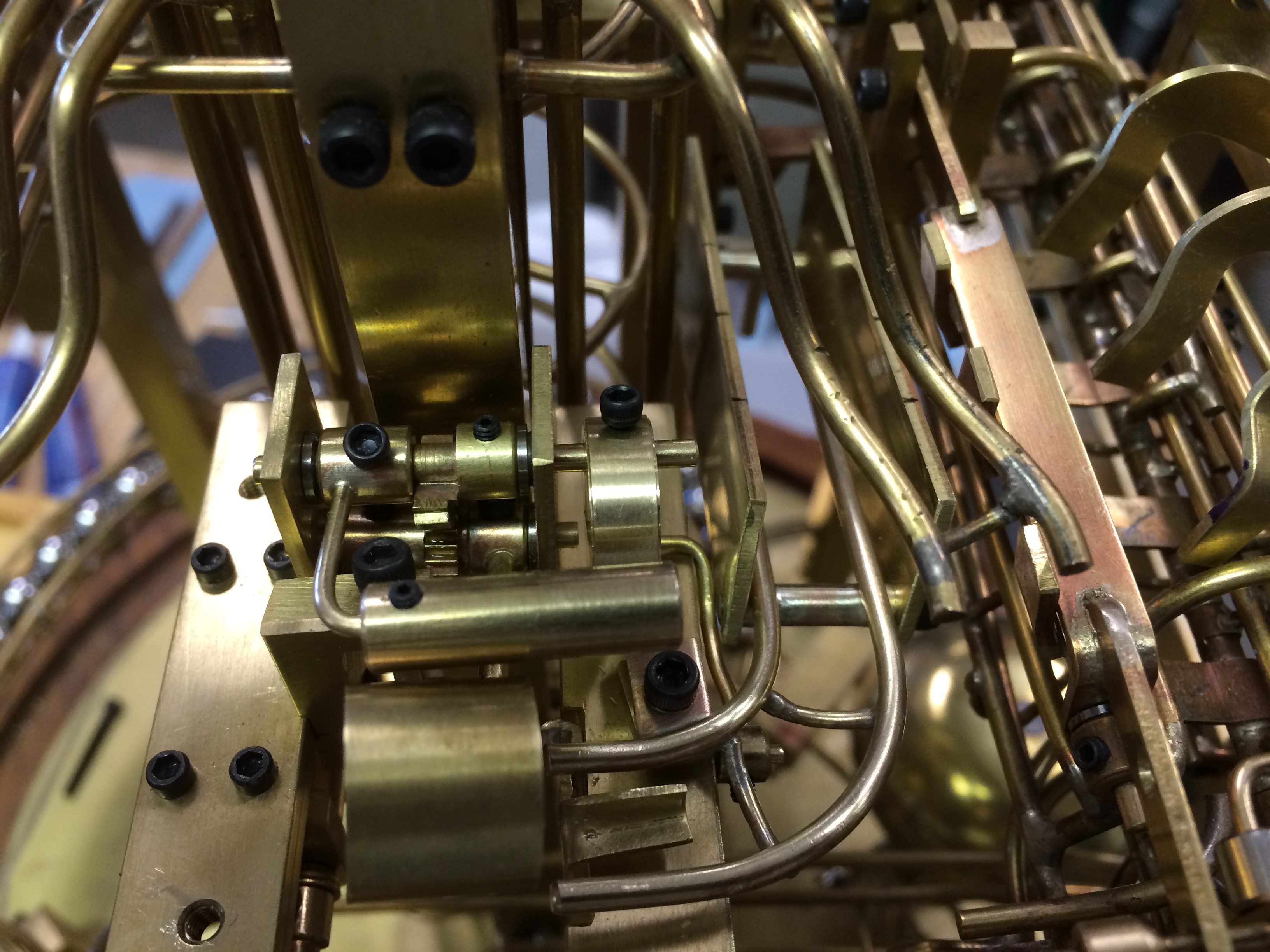

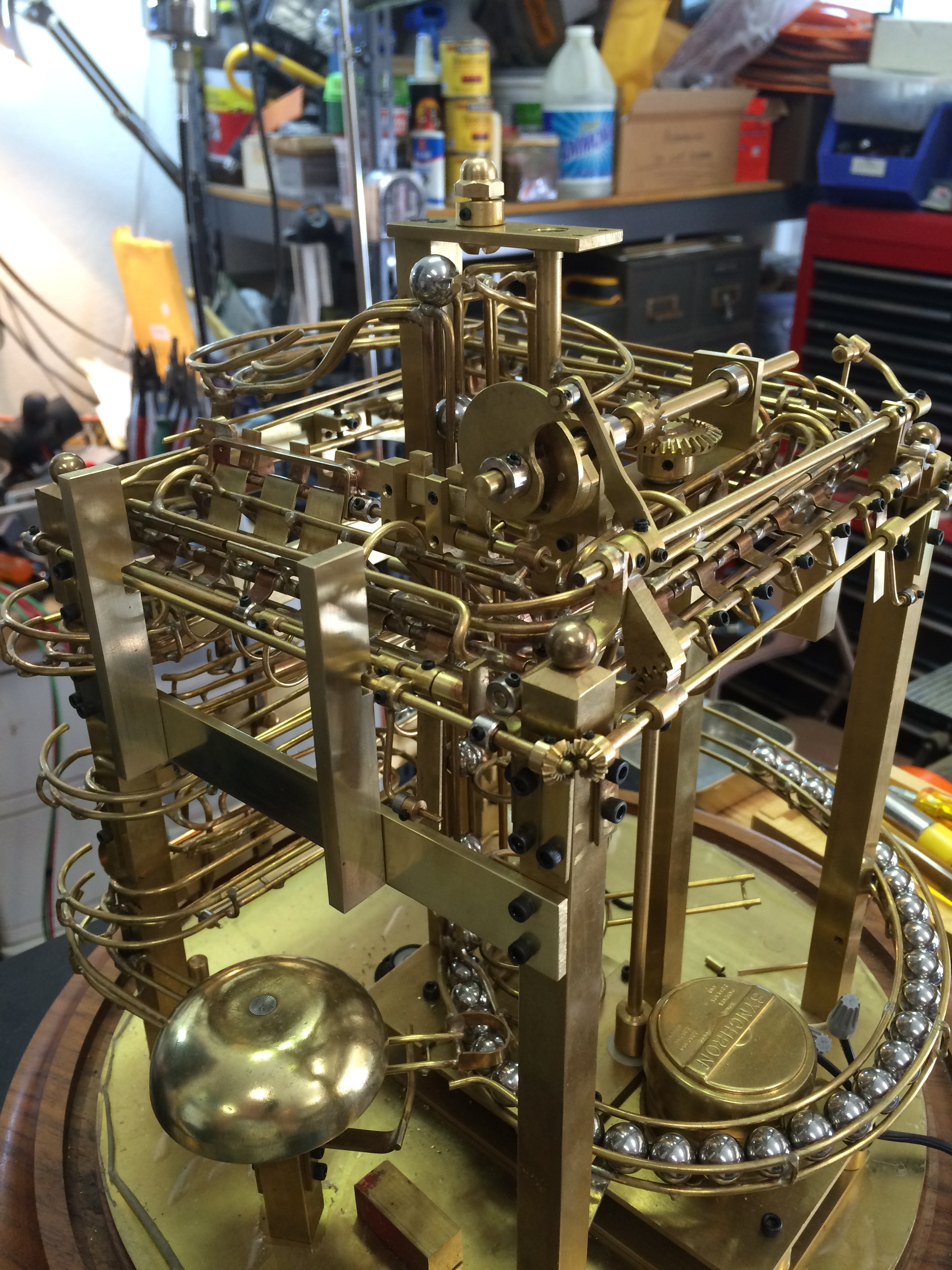

Having completed the quarter ball magazine, it was time to move on to the bell and striking mechanism.

Having completed the quarter ball magazine, it was time to move on to the bell and striking mechanism.

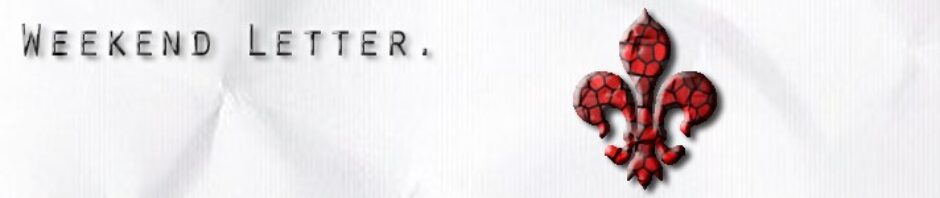

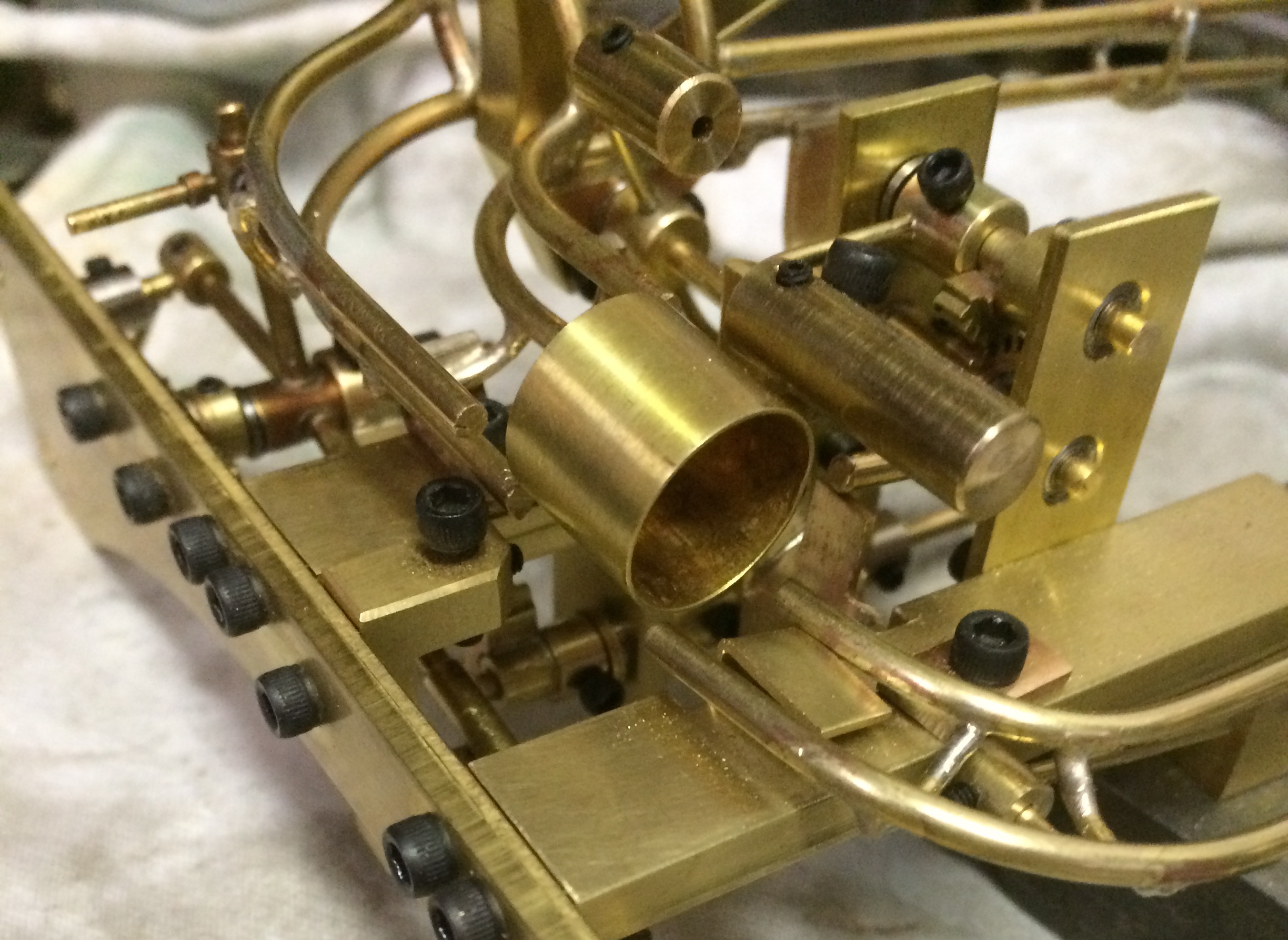

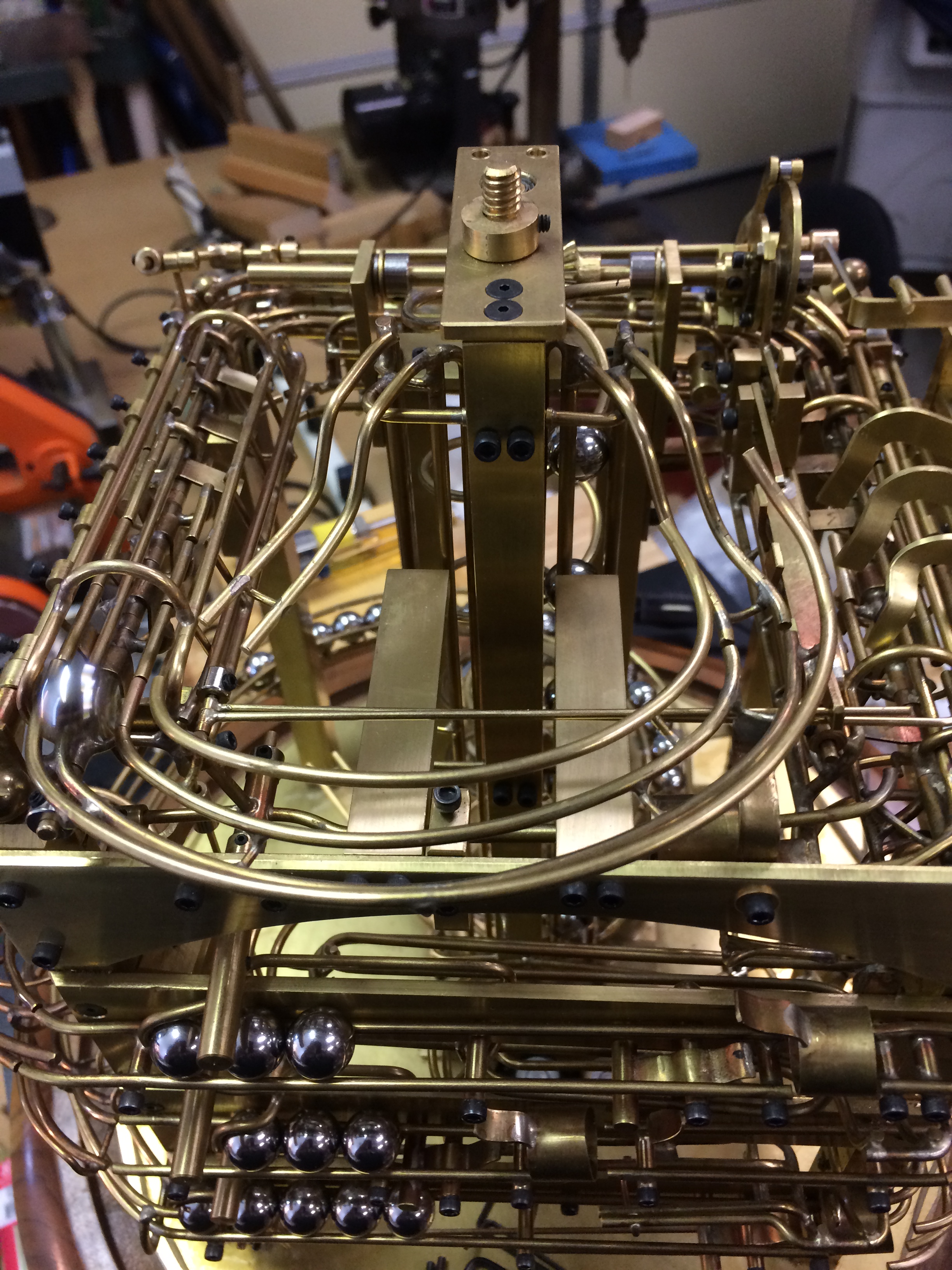

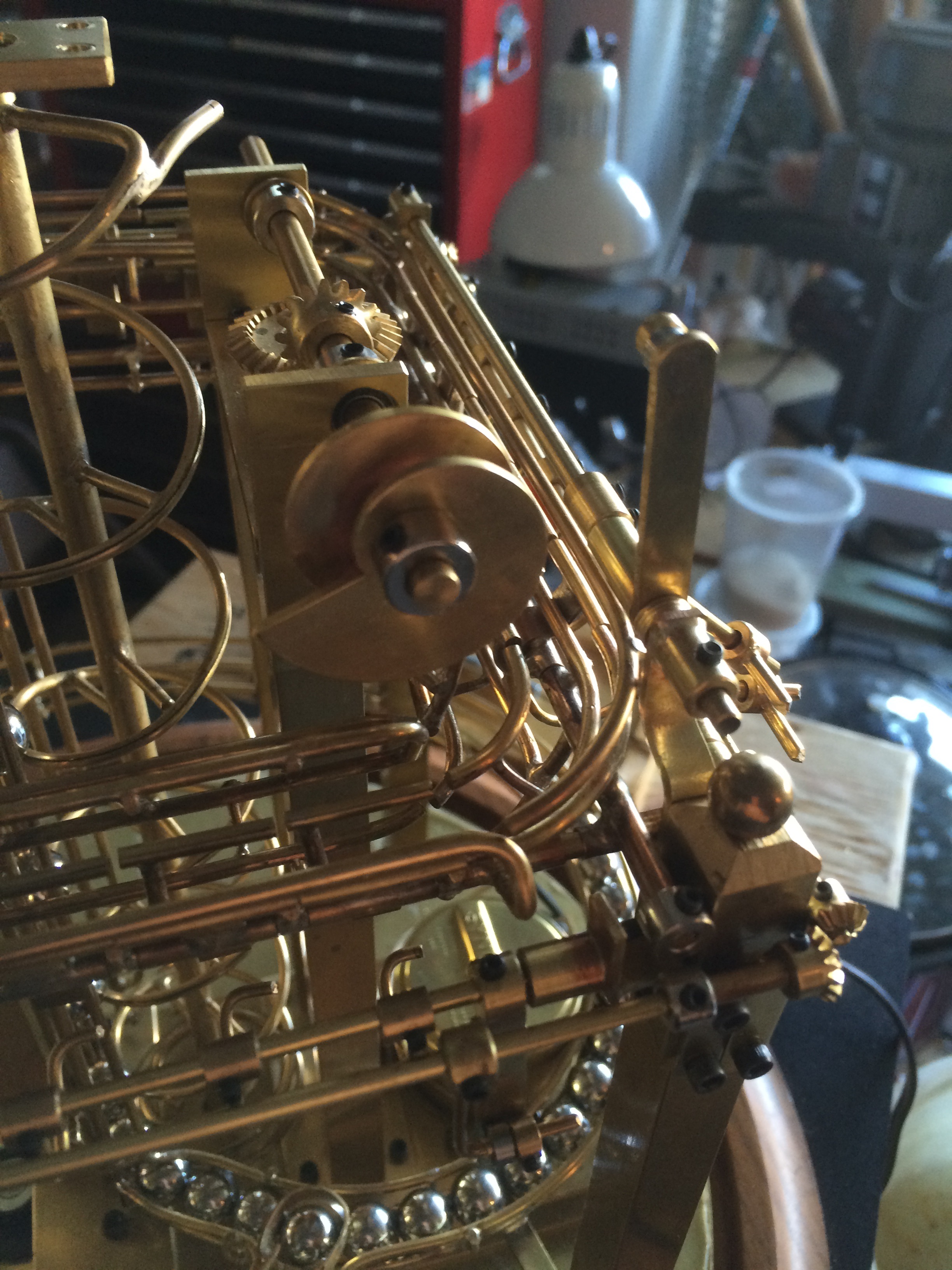

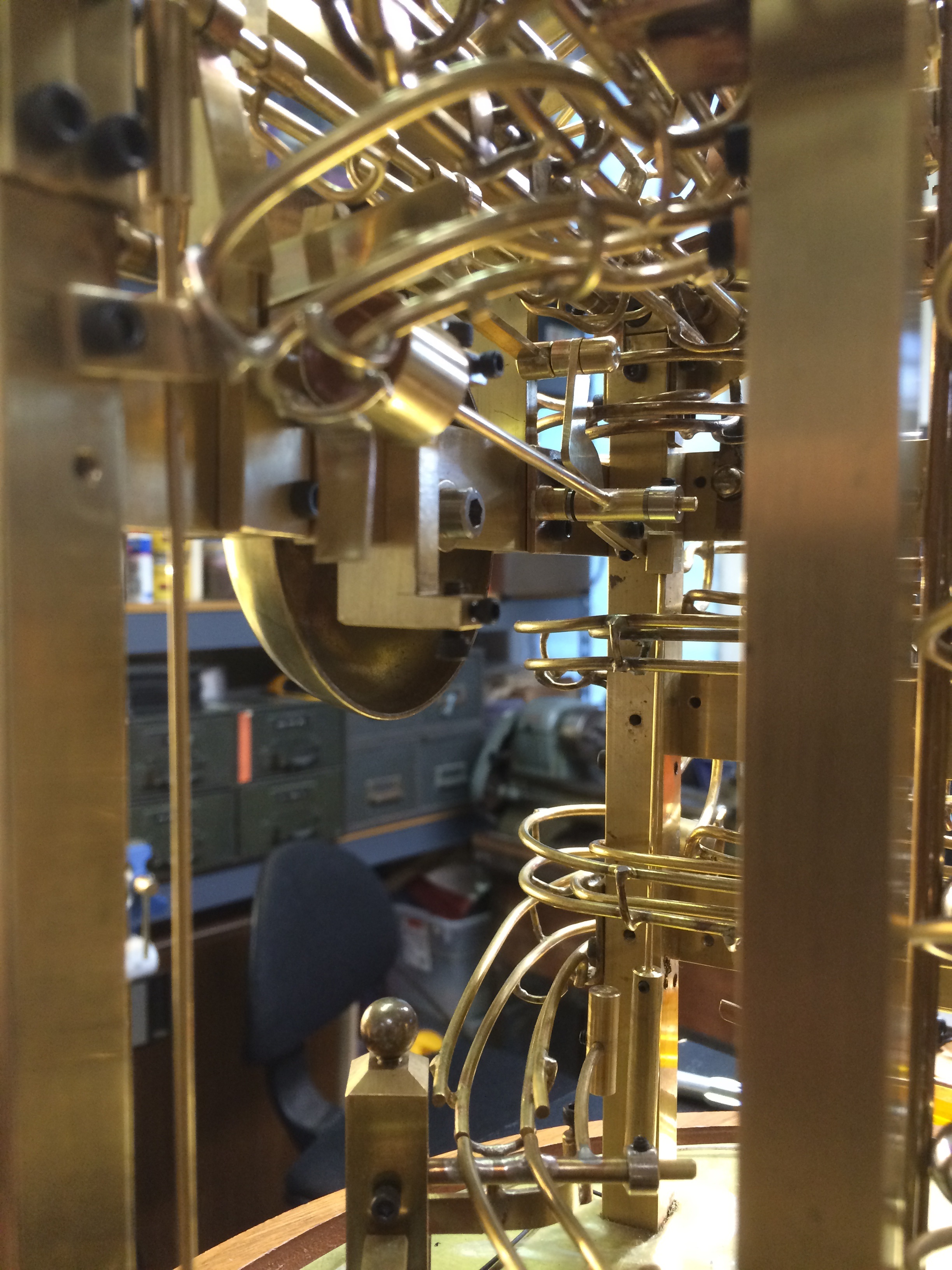

When the balls exit the magazine the drop straight down onto a track that takes them to the level that will use the ball weight to operate the hammer.

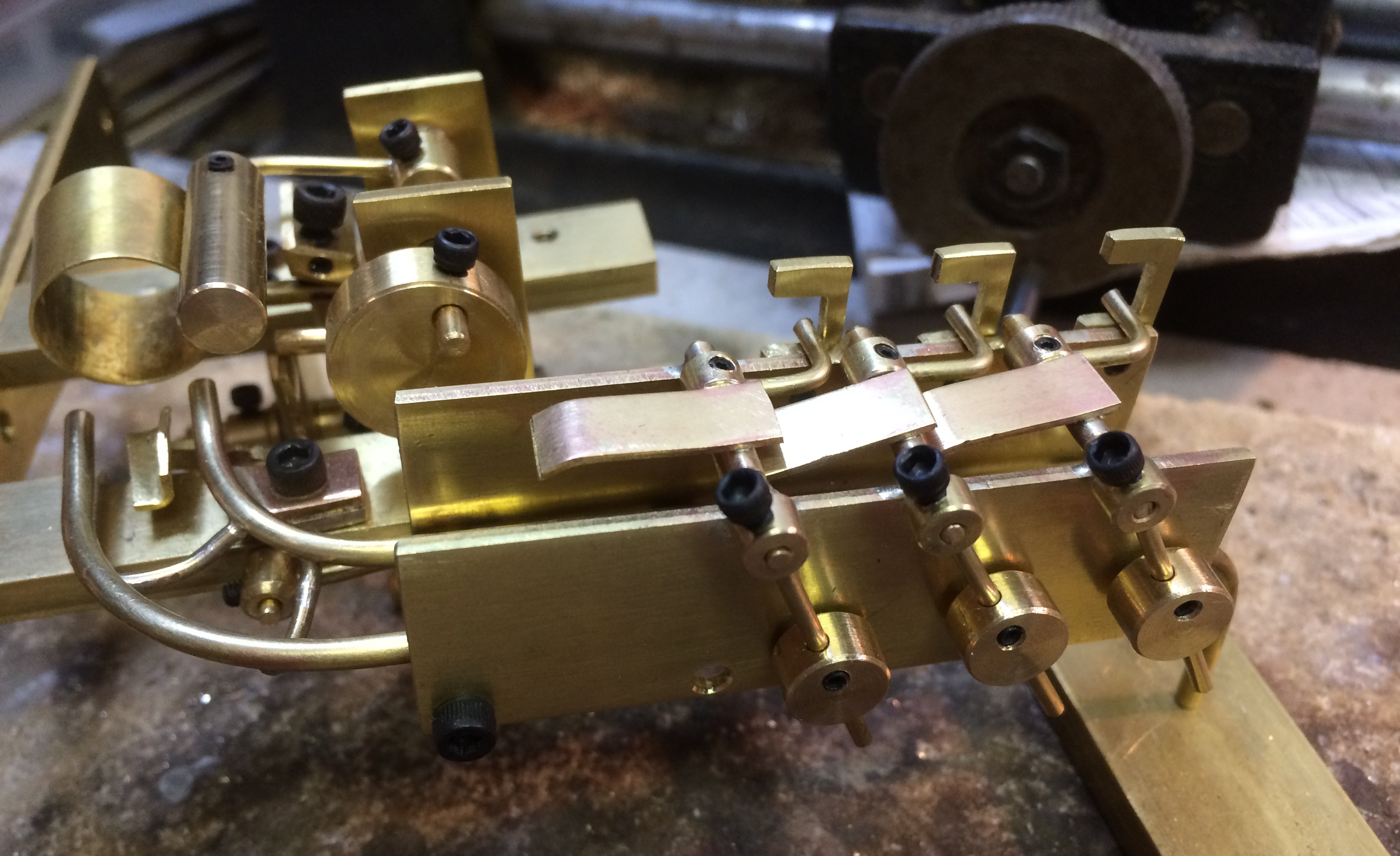

Because there would be multiple balls sometimes, I needed a way to block the balls until a full cycle of the hammer had been completed.

When the ball goes into the cup of the lever, the weight of the ball causes the lever to pivot. This allows a small flat bar to drop in the path of the rest of the balls.

When the ball goes into the cup of the lever, the weight of the ball causes the lever to pivot. This allows a small flat bar to drop in the path of the rest of the balls.

When the lever returns, it pushes the bar up so that another ball can enter the cup and the cycle starts again.

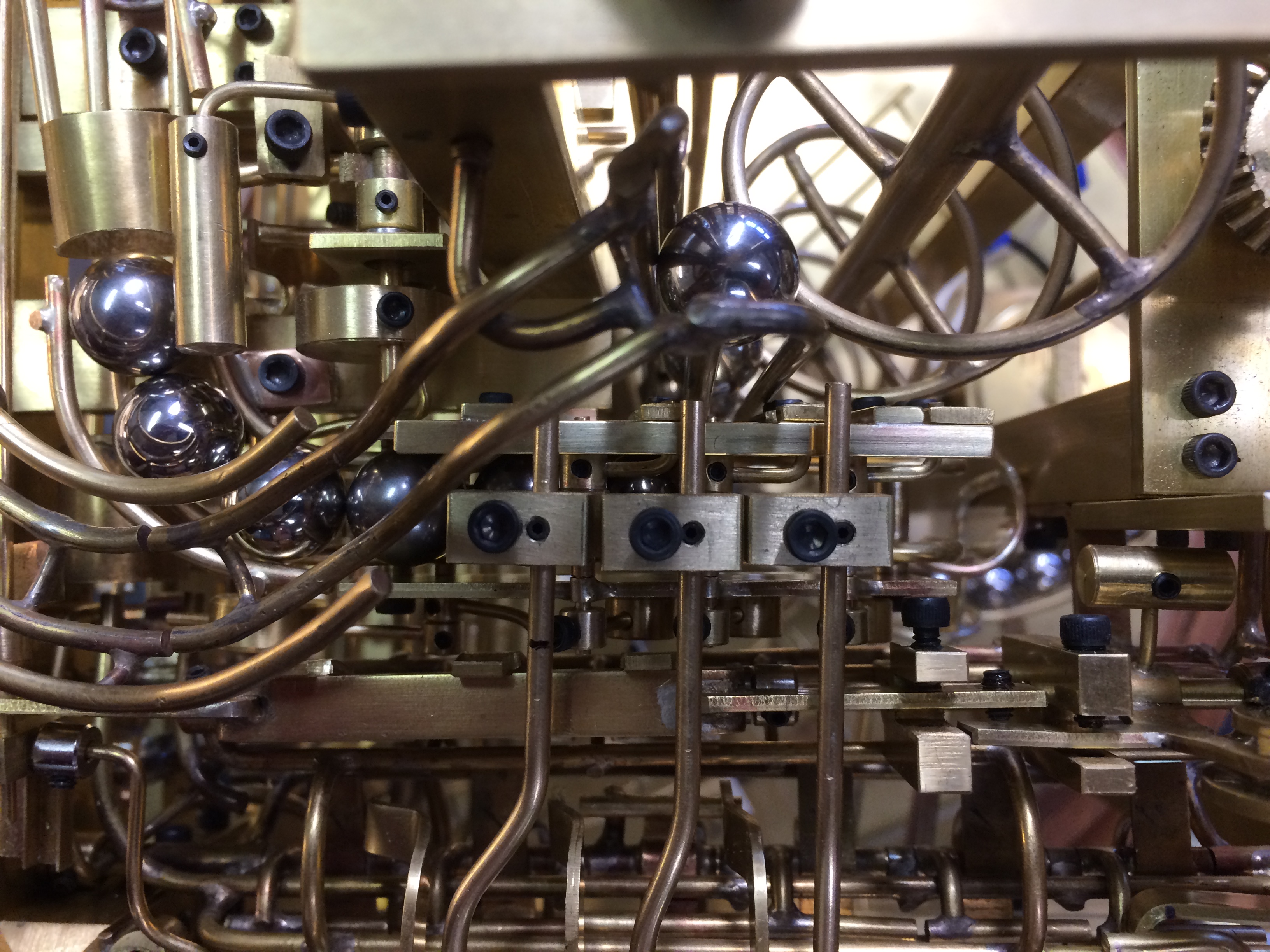

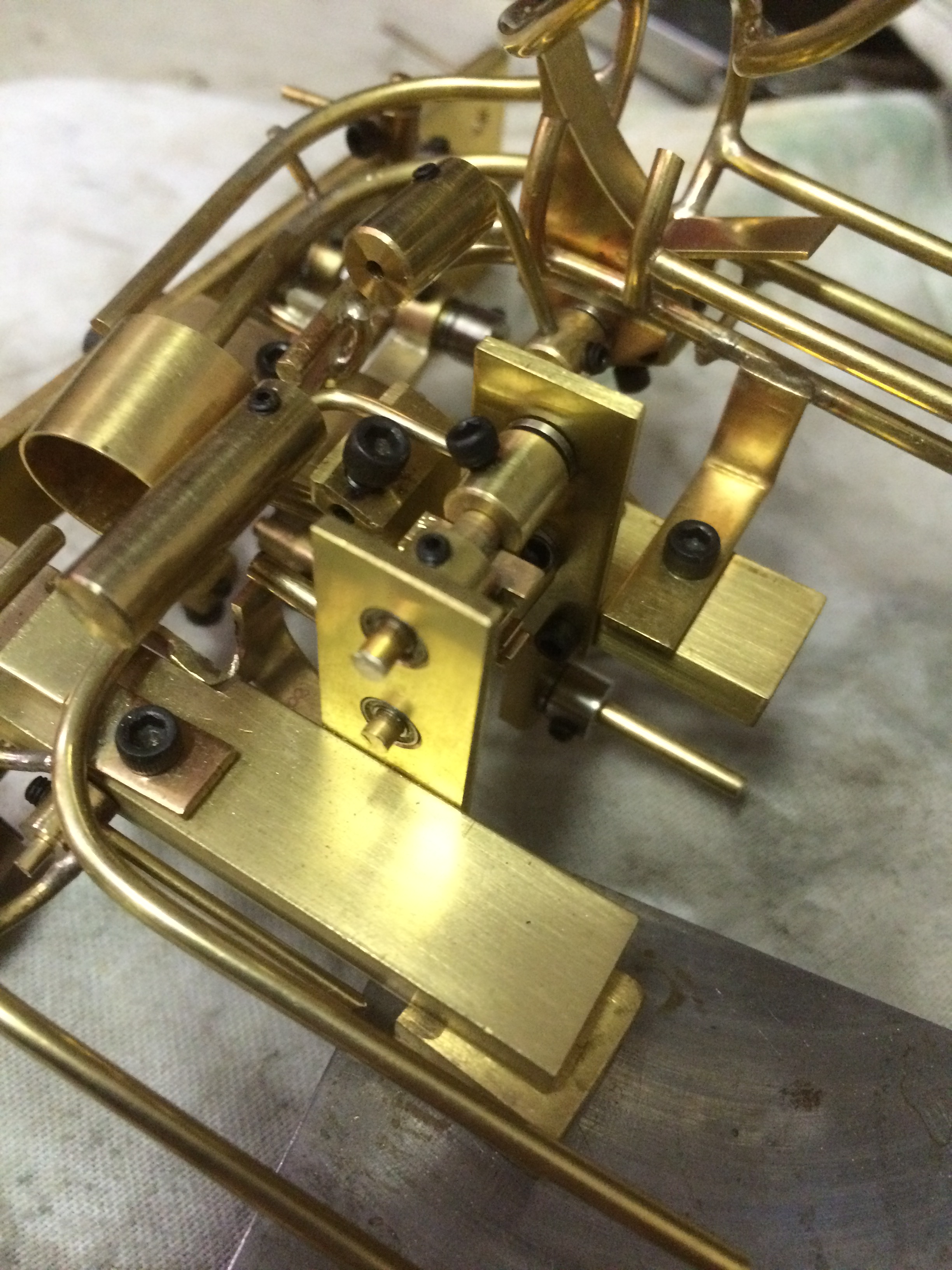

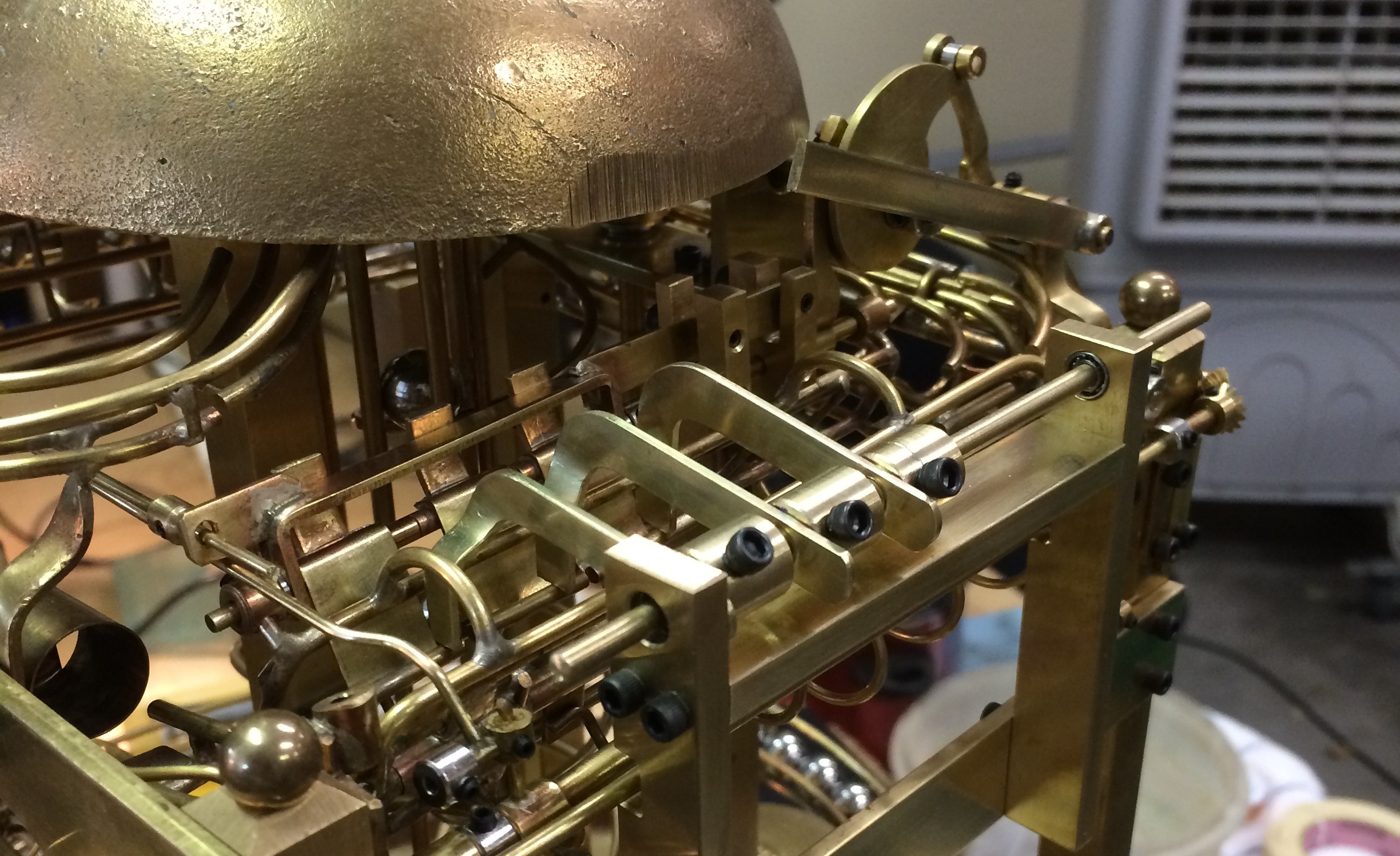

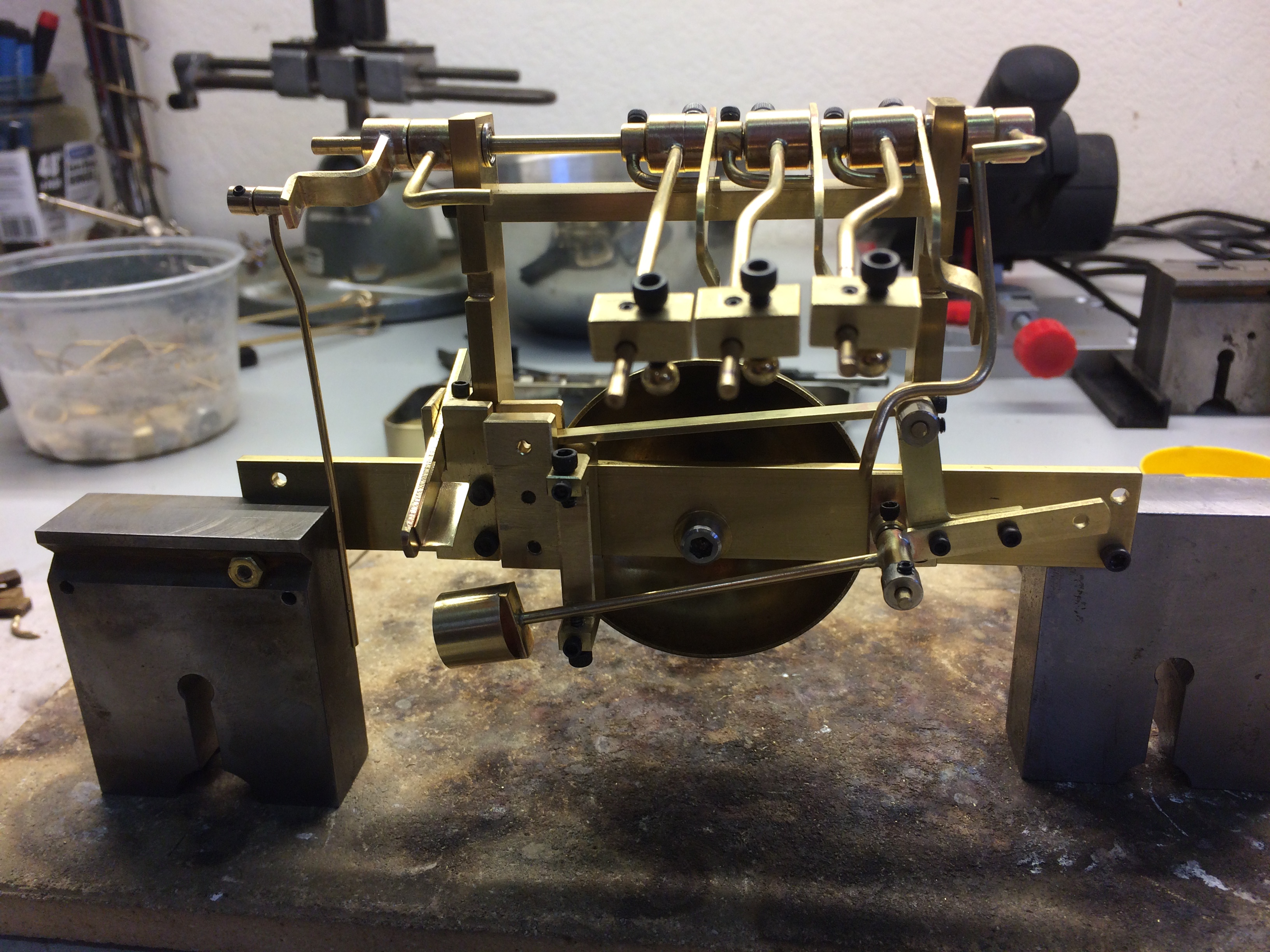

I noticed that the strike came fast, too fast, so it will require another solution to slow the strike down.

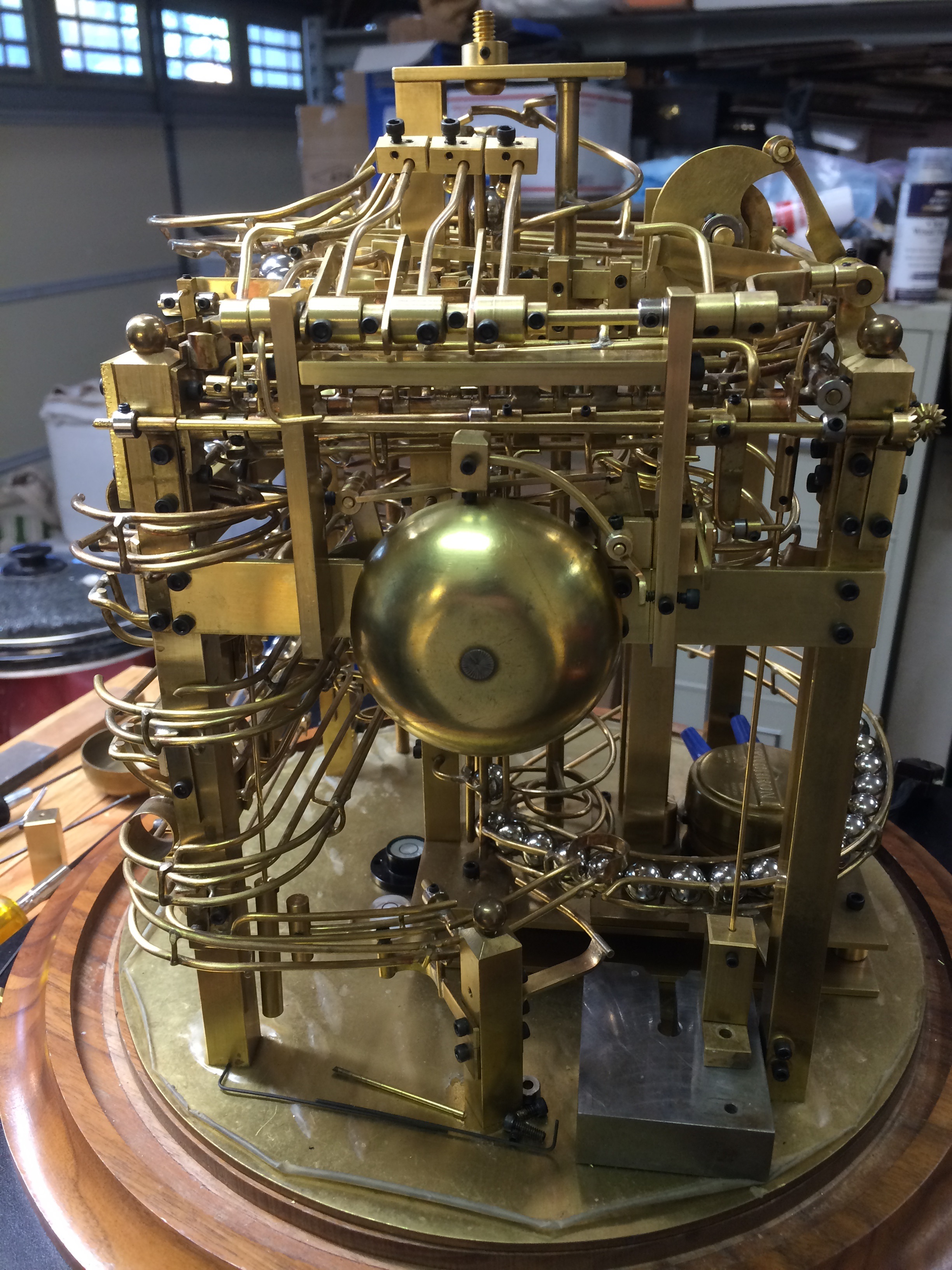

The bell is from a old telephone chime. I believe from the 1970s.

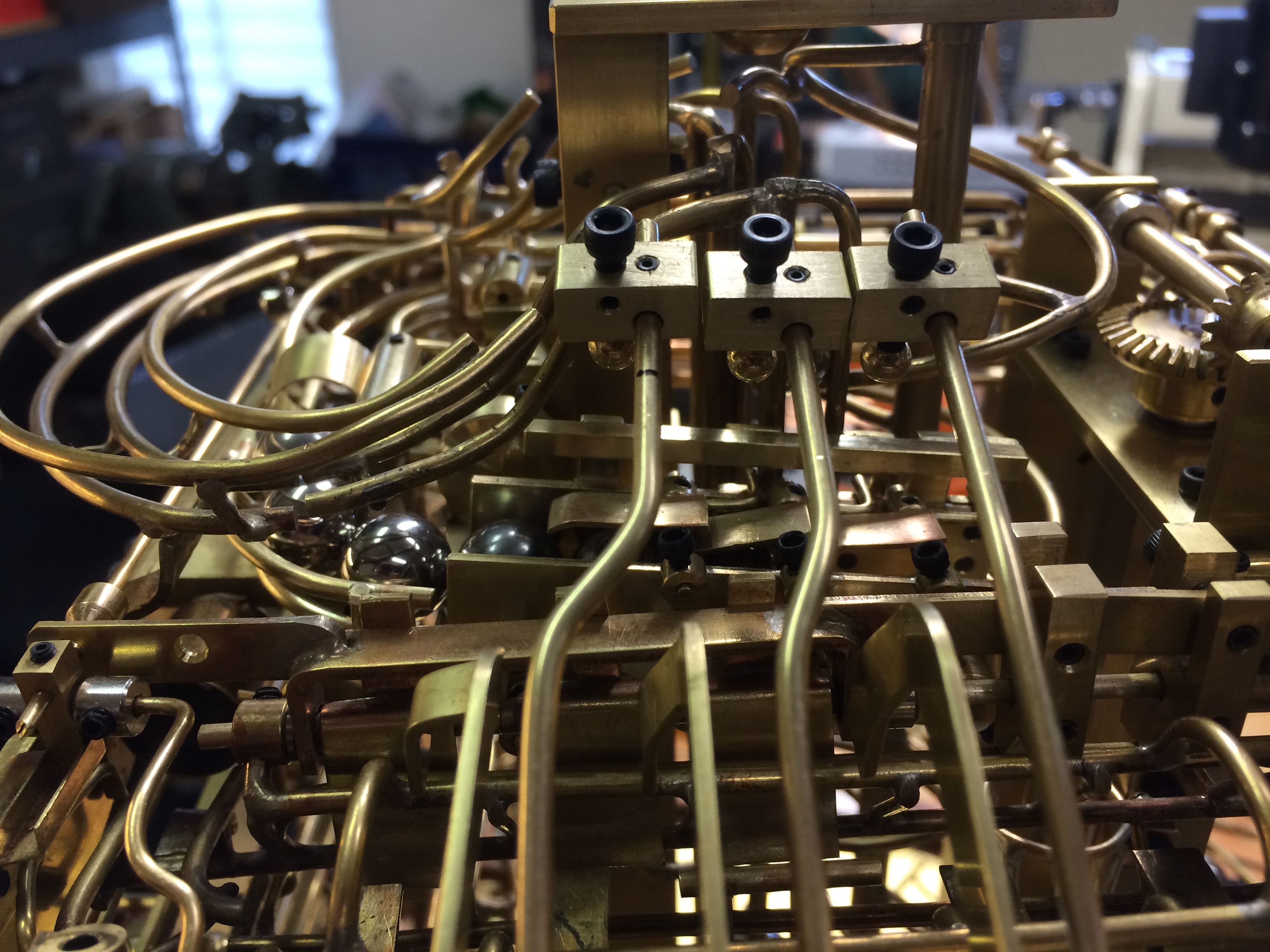

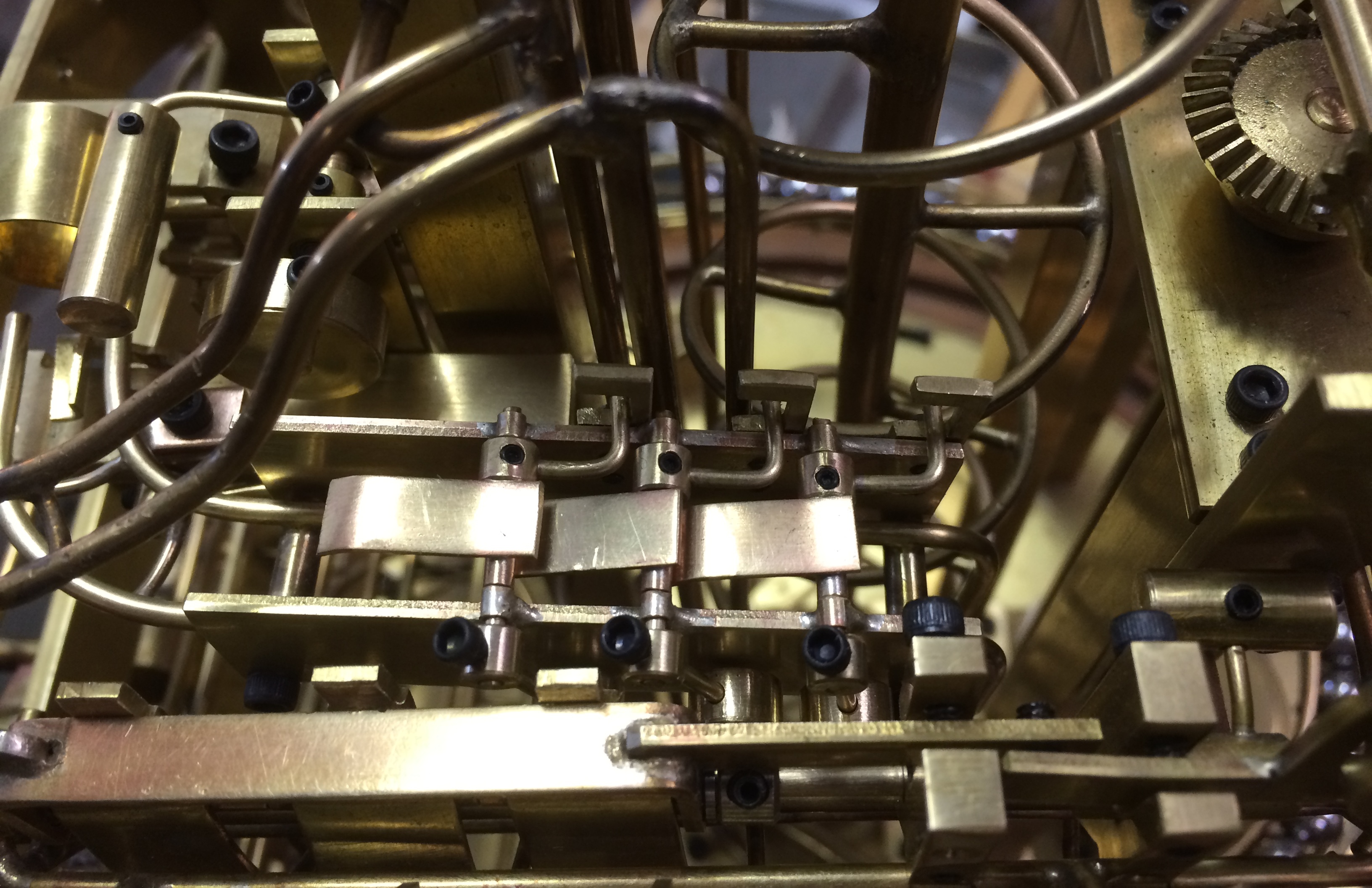

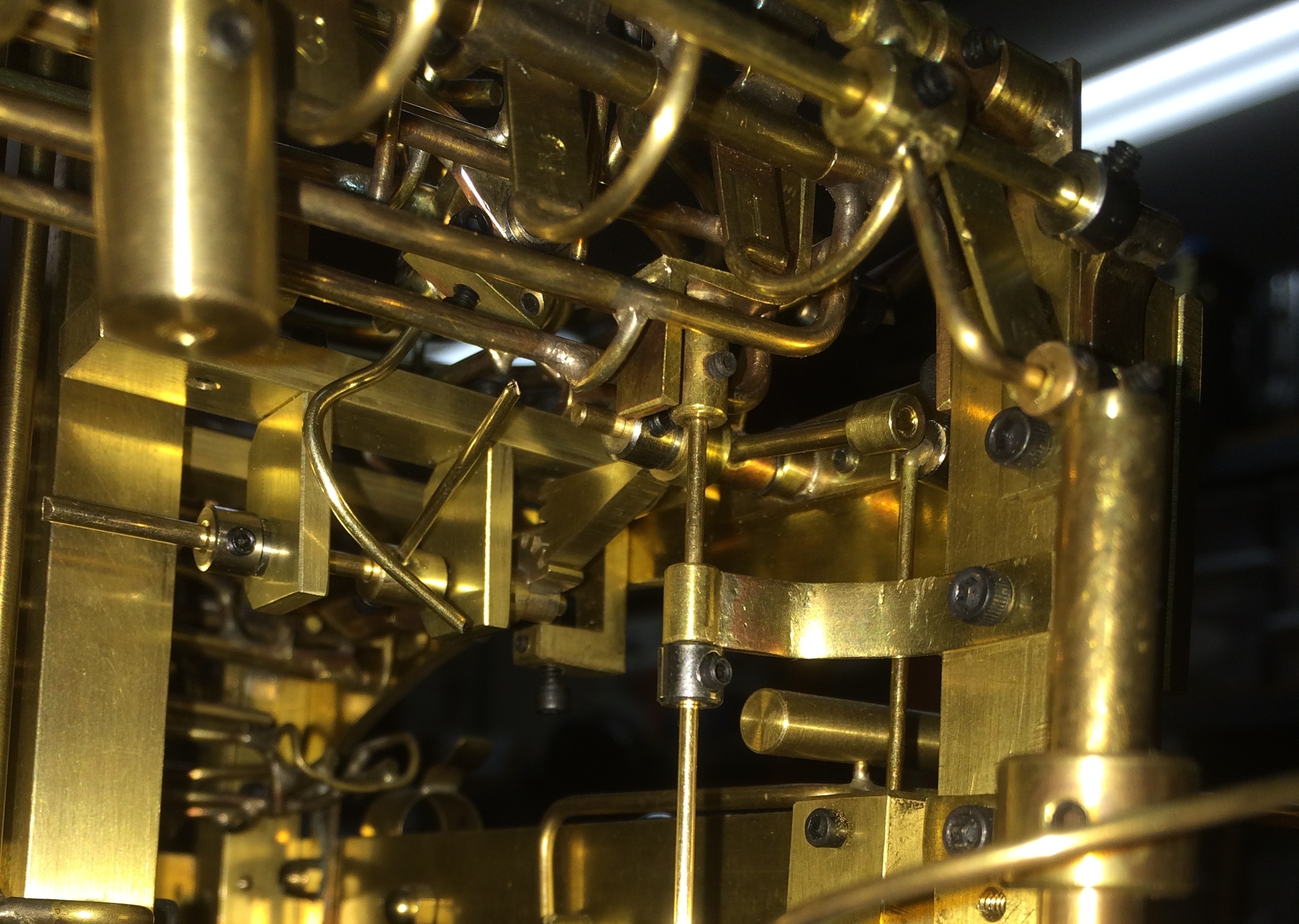

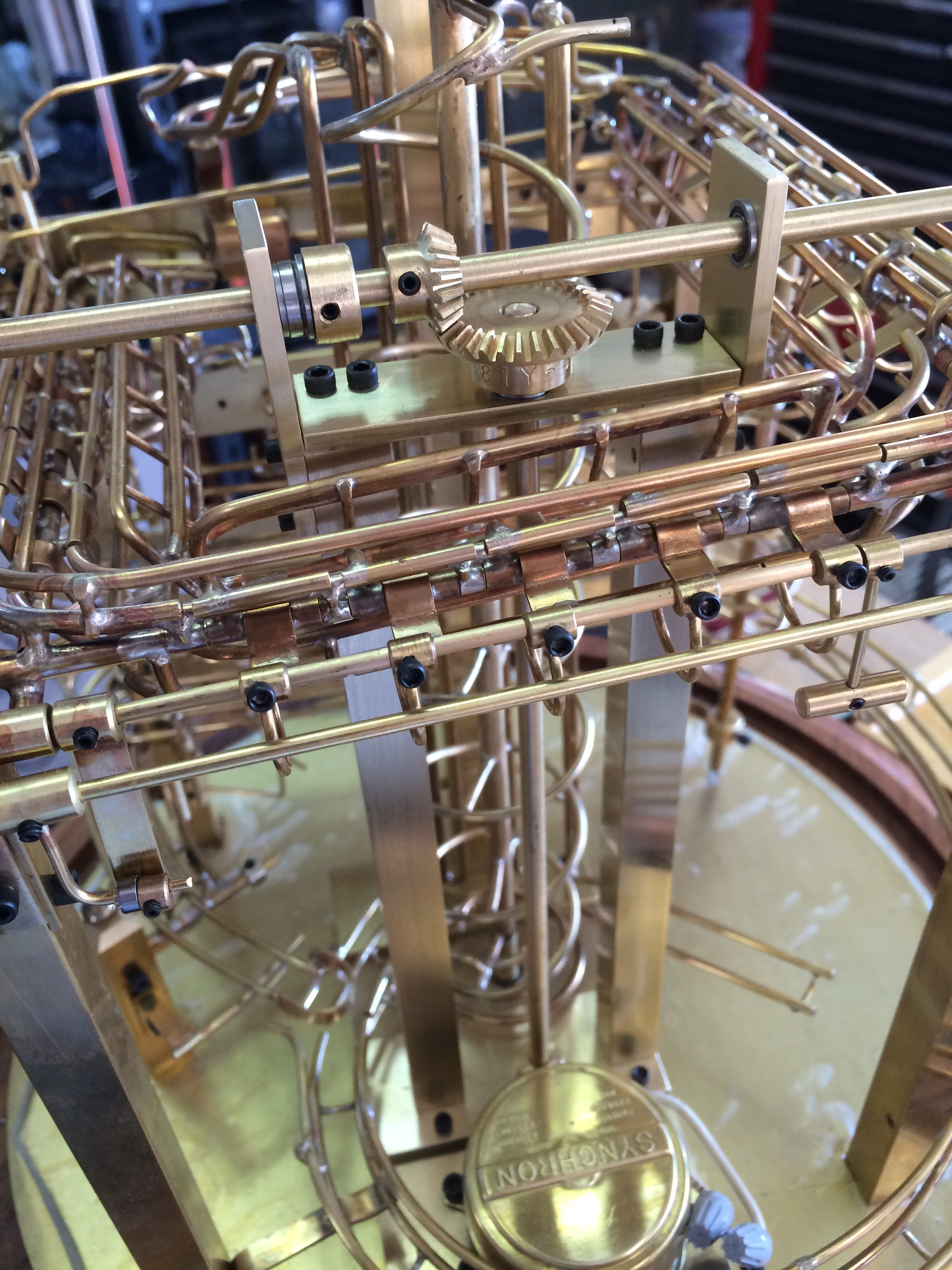

When the level drops it pushes a rod that engages a block attached to the hammer shaft. The shaft is rotated, the hammer lifted and just before full throw, the rod slips out of the block and allows the hammer to fall.

There was a balancing act going on here as the weight of the hammer applies pressure against the weight of the ball powering the lever.

There was a balancing act going on here as the weight of the hammer applies pressure against the weight of the ball powering the lever.

Getting the throw just right took some time.

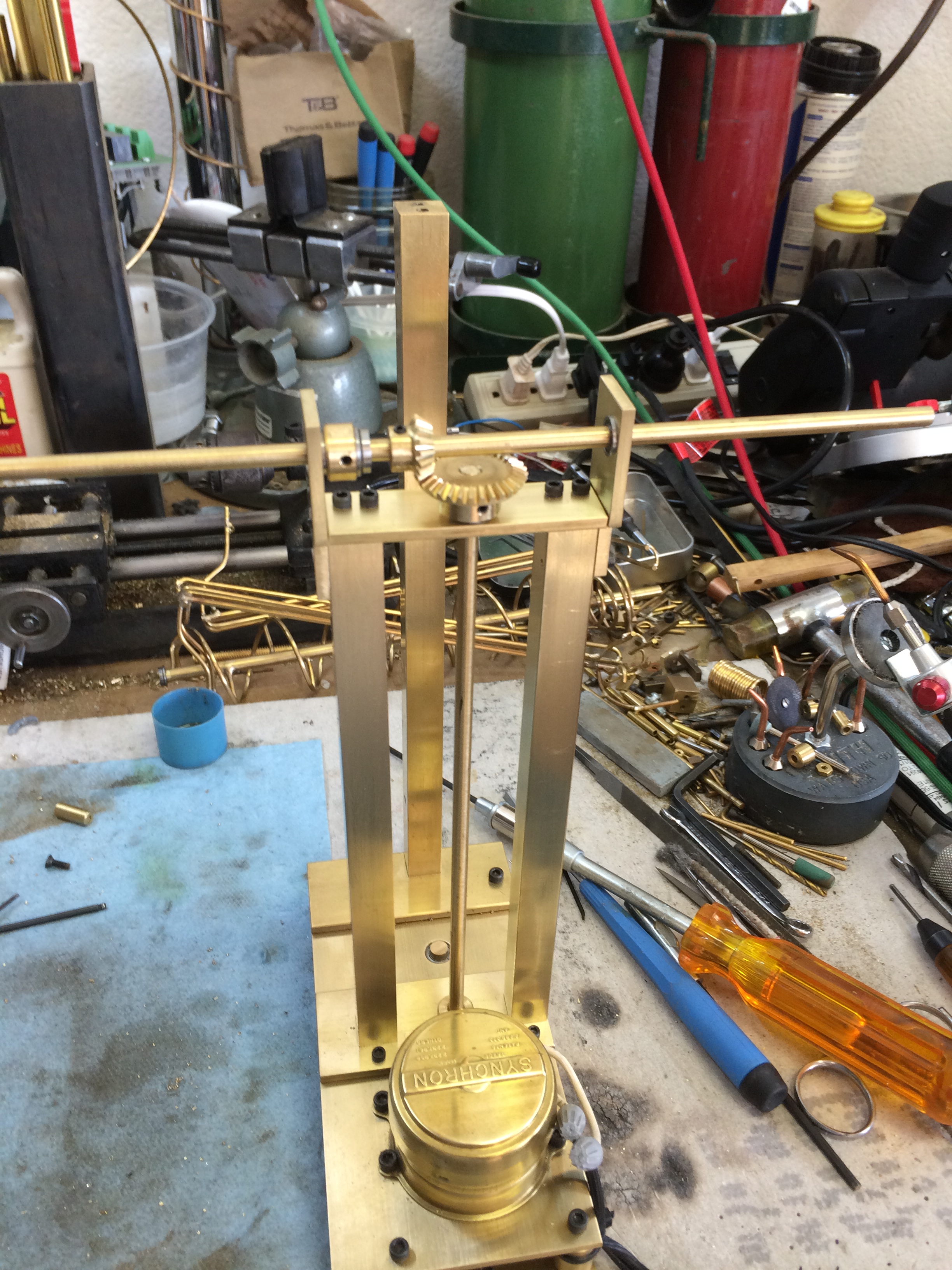

Everything was mounted to the same frame as the feelers so it could be removed as a single unit.

Now to work on dealing with the balls from the striker as well as the ones from the excess drop.