In my early years, my third real job after Putt Putt Golf & Trains & Planes toy store was with National Cash Register. For you younger ones, it is now called NCR, as they moved into the electronic age, the original name lost it’s buzz I guess and Point of Sale became the thing. For 16 years, NCR provided me with a wonderful education on many mechanical and electronic machines. Back in the day (1960s) some had over 33,ooo mechanical parts. It always amazed me as to how well they worked. Of course when they didn’t, that is when I came in. As a Service Technician and later instead of a raise, a Field Engineer, it was my job to find the issue and fix it. Everything wears out eventually so there was job security until the transistor and integrated circuit took over.

Anyway, NCR always built their mechanical products on a good base. Usually cast iron. Something my back tells me about today.

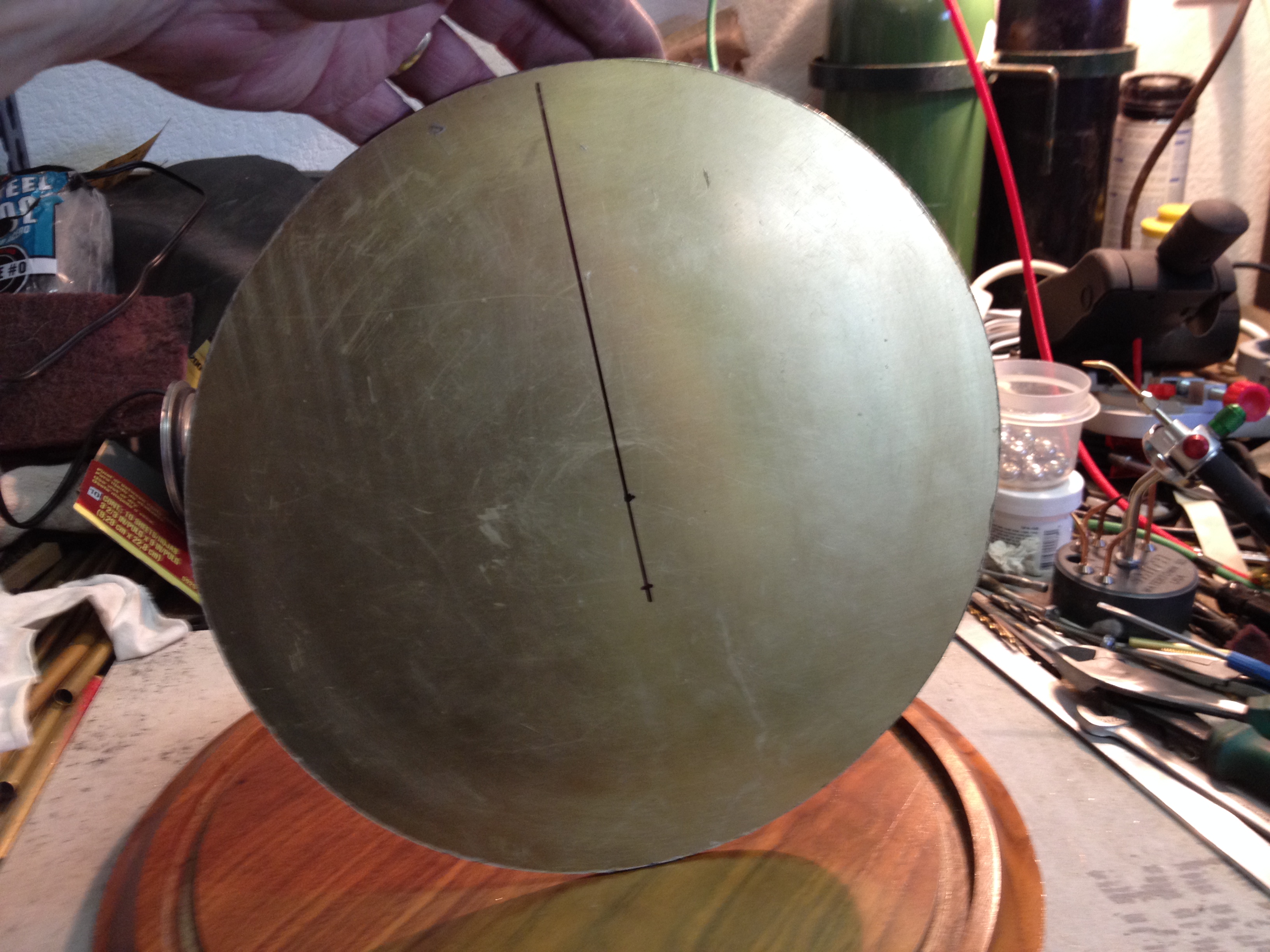

So, I wanted to have a good base for this clock and picked up a sheet 12″ X 24″of 1/8″ brass from a local supplier, which I could make 2 bases out of if needed. Brass is a alloy of Copper & Zinc and while it looks like gold, it is considerably less expensive. However this piece cost me $50. I’m starting to think this may get expensive before I’m finished.

It was time for a new tool as the prospect of cutting this plate by hand did not appeal to me.  A quick trip the Harbor Freight after shopping Home Depot netted me a medium duty band saw that will do the trick without breaking the bank.

A quick trip the Harbor Freight after shopping Home Depot netted me a medium duty band saw that will do the trick without breaking the bank.

So I cut out a round plate to fit on the bottom. From this I will mount all the framing and structure of the clock.

Now that I have the “Playing Field”, what to put on it?

Rule #1: Something I have not seen before.