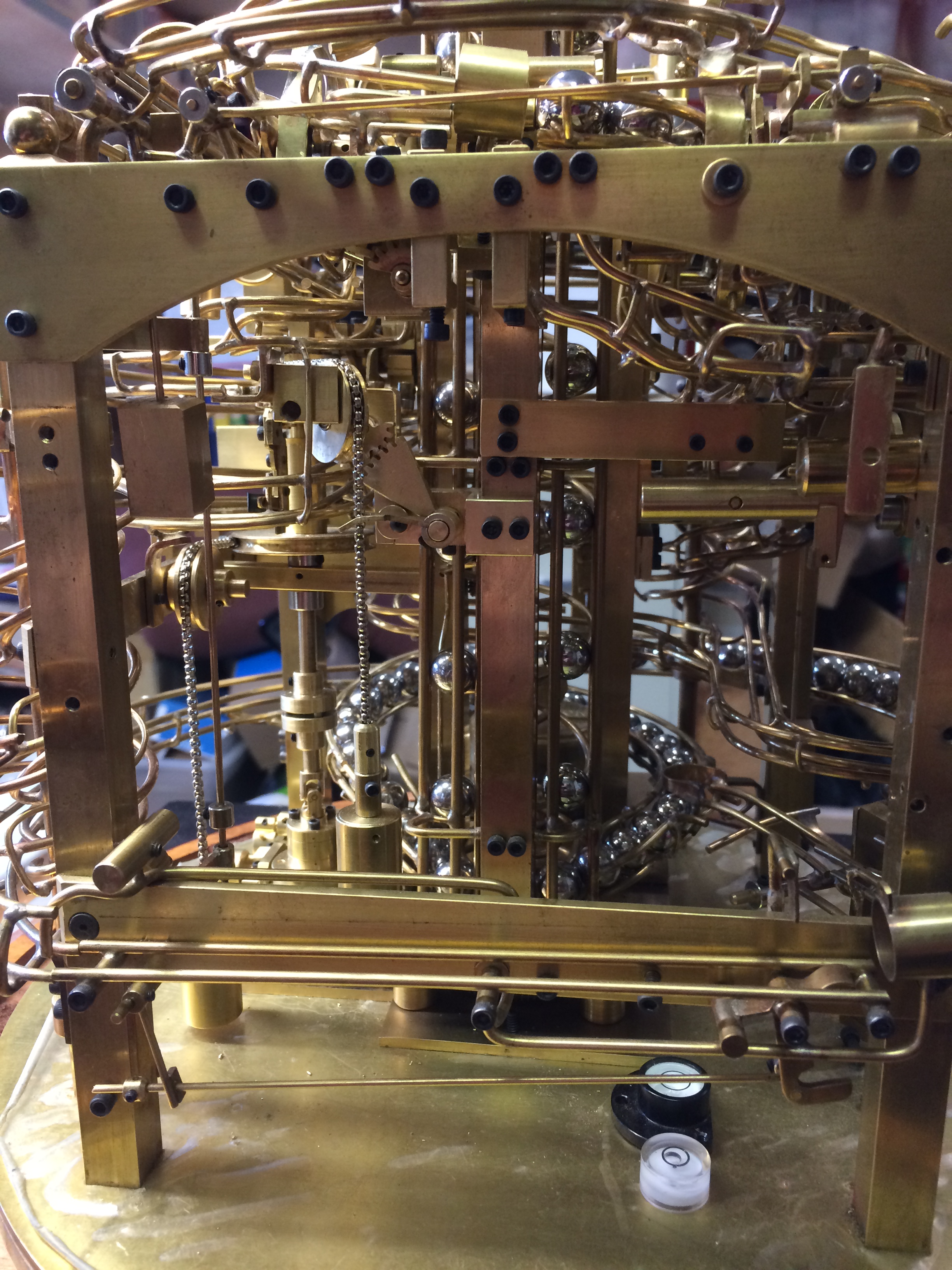

One of the things I had to consider with the design of the Hour Selector mechanism was what to do with the balls that accumulated one every hour. By the time 12 o’clock comes around the track holding these balls was filled to capacity.

By the time 12 o’clock comes around the track holding these balls was filled to capacity.

Something had to be done to release (dump) these balls before 1 0’clock came around.

The trick was to find something in the works that only happened at 12 o’clock and no other time.

Then be able to trip another cycle to allow the 12 balls in the rack to exit.

Also and very important, the balls could not exit at the same time the clock was striking 12 since they used some of the same exit path back to the screw lift.

This could have caused a ball jam from balls hitting each other running down the same track.

When the hour selector is stopped by a ball in the rack, it engages another cam that opens a gate to allow that selected number of balls to move to the hour hammer trip area. Because this happens immediately at the start of the selection at 12 o’clock, it is the longest rotation the cam makes. At the end of the cycle to provide power to return the cam to its home position a chain is attached to it and a weight. Now because this is the longest travel the chain will make, I had a spot that I could monitor.

When the hour selector is stopped by a ball in the rack, it engages another cam that opens a gate to allow that selected number of balls to move to the hour hammer trip area. Because this happens immediately at the start of the selection at 12 o’clock, it is the longest rotation the cam makes. At the end of the cycle to provide power to return the cam to its home position a chain is attached to it and a weight. Now because this is the longest travel the chain will make, I had a spot that I could monitor.

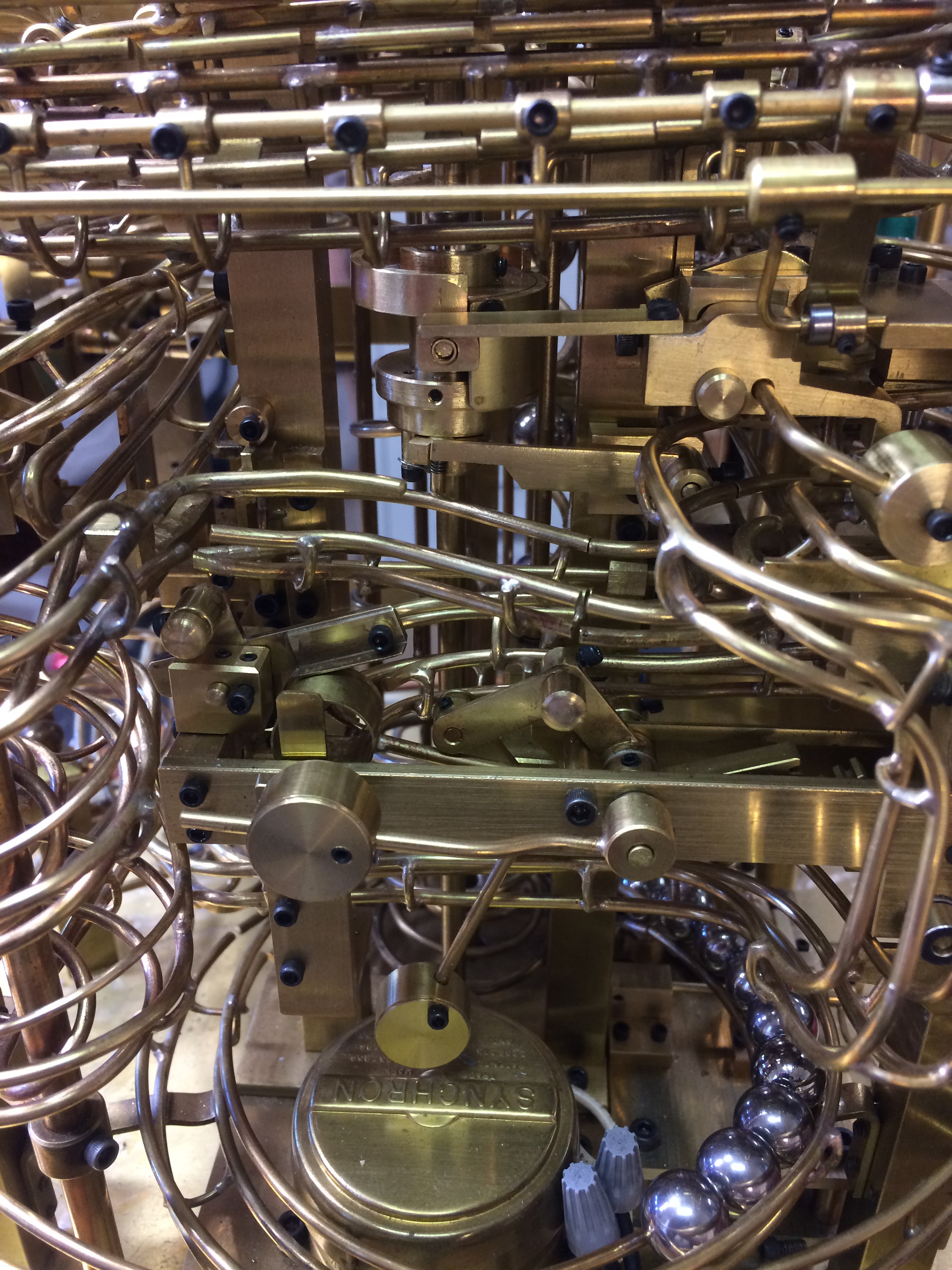

By making an arm with a slot that straddled the chain and putting an adjustable collar on the chain, I was able to have an action occur only at 12 o’clock. The collar contacts the arm and moves it up rotating a gear and turning a shaft that goes to the other side of the clock.

On the other end of that shaft is an arm that releases a clutch pawl to engage and clutch.

The clutch engages a cam, that when it turns, moves an arm attached to the gate holding back the hour balls.

The cam that moves the release arm for the balls is 285 degrees around from the engagement point of the clutch. Because the shaft that the clutch is on turns are 2.5 rpm, the minimum amount of time before the gate is opened is 20 seconds and a maximum of 44 seconds.

The cam that moves the release arm for the balls is 285 degrees around from the engagement point of the clutch. Because the shaft that the clutch is on turns are 2.5 rpm, the minimum amount of time before the gate is opened is 20 seconds and a maximum of 44 seconds.

It takes 18 seconds for all 12 balls to strike the hour. This allows a clear track for the 12 balls to exit when dumped. And yes that was fun to figure out. I wonder sometime what I got myself into.

For the next 12 minutes balls on the supply lift for striking will be diverted to fill up the lower track of the hour selector since twelve were used for the strike.

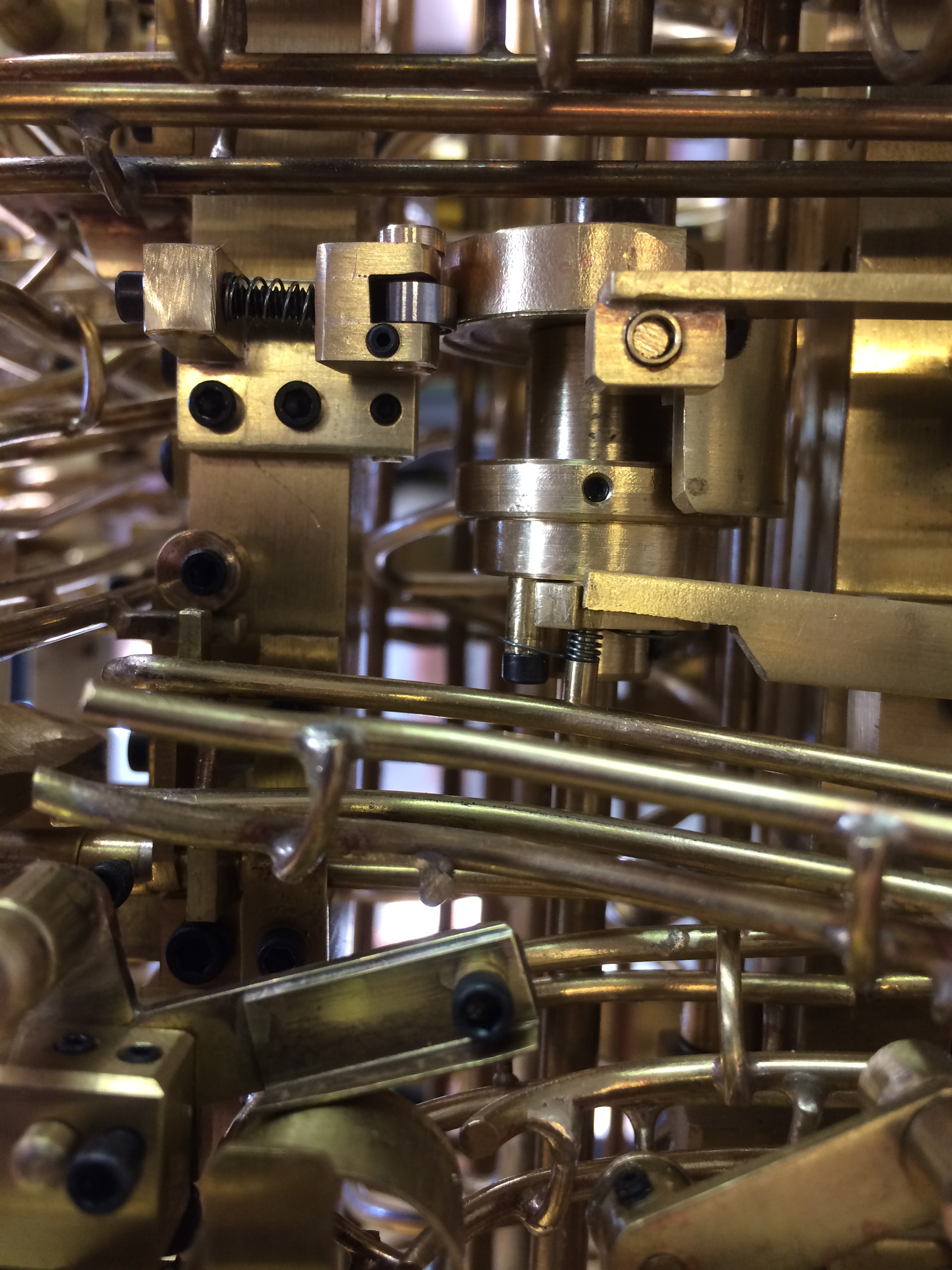

I soon discovered that I needed a way to keep pressure on the cam to keep the clutch pawl engaged. I solved this by making a small spring loaded arm with a bearing to ride on the cam. I cut an index slot on the cam to create a home position. This made the engaging of the clutch dependable.

Now since this was the last major mechanism, it is time to do some base work.